Stainless Steel Weld Neck Flanges Manufacturer and Supplier In Mumbai, India

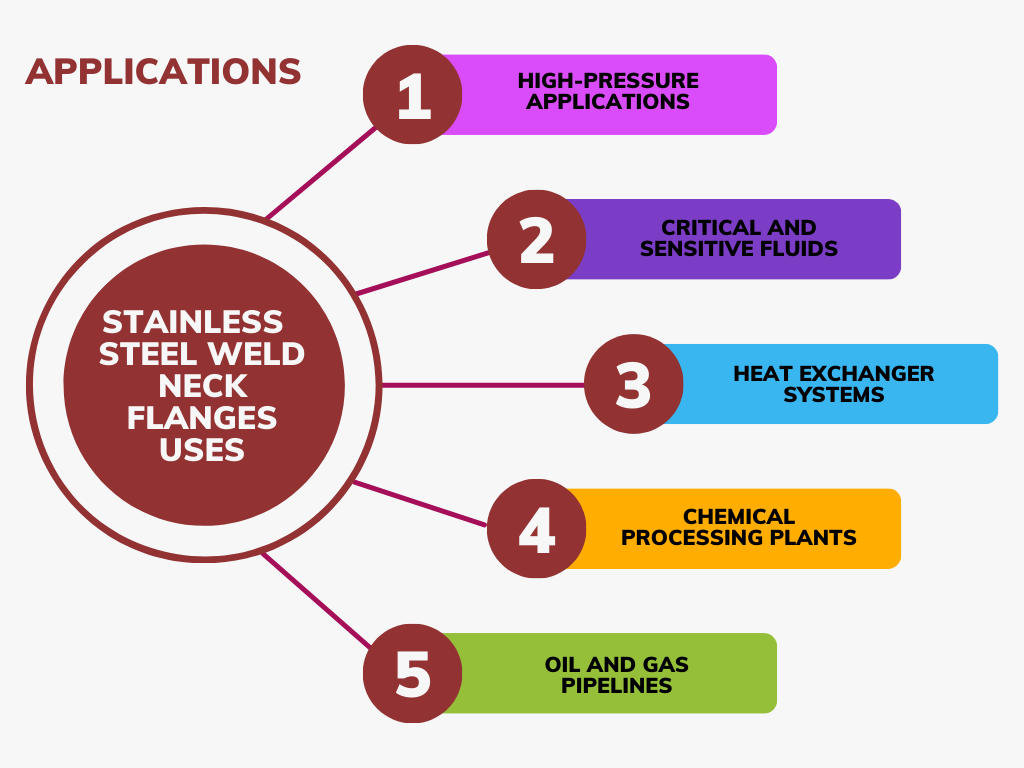

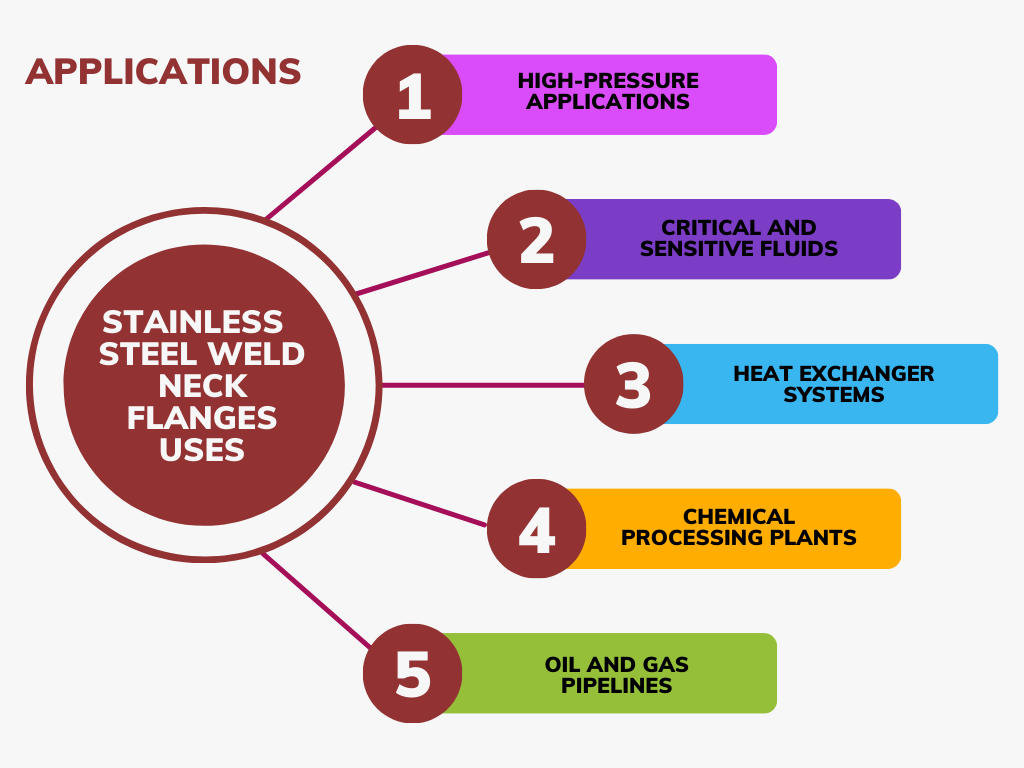

A stainless steel weld neck flange is a type of flange that is welded to the end of a pipe. It is

the strongest and most leak-proof type of flange, and is often used in high-pressure and

high-temperature applications. Weld neck flanges are also used in usages where vibration is an

issue, as they are less likely to loosen or leak than other types of flanges. Stainless steel weld

neck flanges are commonly made from austenitic stainless steel metal grades such as 304 and 316, which are

known for their excellent corrosion resistance. They are available in a variety of sizes and

pressure ratings, and can be used with various pipe schedules. Applications of stainless steel weld

neck flanges working in chemical processing, petrochemical processing, power generation, oil and gas

production, water and wastewater treatment, marine and offshore applications, aerospace and defense.

Weld neck flange parts are used in these applications owing to numerous weld neck flange advantages.

We, Naysha Steel and Alloys, are a leading manufacturer and supplier of Stainless Steel Weld Neck

Flanges in Mumbai, India. With years of experience and skill, we have established

ourselves as a reliable name in the industry. We, at Naysha Steel, are

known for delivering high-quality weld neck flanges that obey the international standards, European

standards for weld neck flanges. Our 316 stainless steel flanges are used widely for many industries, namely oil and gas, petrochemical, marine, and

power generation. We pride in being an up-to-date manufacturer and

supplier, which enables us to produce weld neck flanges of excellent quality. We are

committed to providing first-rate customer service, timely delivery and reasonable pricing,

making us the favorite choice for Stainless Steel Weld

Neck Flange in Mumbai India and for export markets as well. We are regularly exporting hassle-free shipments to Dubai, UAE, Oman, Qatar, and nearby Gulf regions as we are having all the necessary certifications and compliances required by Dubai, UAE and Oman, Qatar, Saudi Arab (Aramco). Other types include UNS S31803 weld neck flanges manufacturers

in India. Contact us for answering certain queries of yours like how a welded neck flange is

connected to a pipe, is ANSI B16.47 weld neck flange suitable for ss316 or not, and many more.

Stainless Steel Weld Neck Flanges, SS Weld Neck flanges Manufacturer and Supplier In Mumbai, India

Stainless steel weld neck flanges are the reliable workhorses of high-pressure piping systems, in the sense that they are the most common brand of high-pressure piping systems. They have shown excellent performance in the areas that involve high corrosion or temperature resistance and strong connections. The main point is that the reason for their success is the fact that they have a specific pattern. In contrast with flanges that are not welded, weld neck flanges have a narrow transition that gradually links to the pipe. This results in the spread of stress, making the entire structure more resistant to heat and pressure. Additional to that is the joining of the flange and pipe which pushes the weld onto the neck, increasing the load capacity.

Also, it has an unmatched corrosion resistance in comparison with carbon steel; thus, it is perfect for use in industrial plants involving chemicals, marine applications, and oil and gas refinery. You have a wide range of grade stainless steel to pick from; the choice you make will be based on the type of media and temperature you will be using them for. While Stainless Steel is without question the best material for high integrity piping systems, the use of Stainless Steel Weld Neck flanges remain a reliable and versatile solution.

Types of Flange Welding Neck ANSI 150, 24 600 RFWN 500 A105, Welding Neck Flanges 900 Lbs, Welding

Neck Flanges 150 Lbs, Long Weld Neck Flange ASME B16.5, Weld Neck Std Gasket, Weld Neck Stainless

Steel Flanges in Mumbai, India

Stainless Steel Weld Neck Flanges means a flange having a long tapered hub that is used for high

pressure and high

temperature applications because the hub provides great support and strength to the pipe. Also known

as a long radius weld neck flange,

these SS Weld Neck flange assembly has a long neck length, which allows for easy connection

to the pipe and provides better

control of the flow.

The design of a weld neck flange, in particular, is that it has a neck that welds the entire pipe together during welding. The aven carrying face of our design creates an area that receives all the pressure and therefore enhances the device's containment abilities in higher pressure areas. By use of flanges, either welding it permanently or bolting temporary, this measure is easy maintenance and radiating. Certain type of weld neck flanges include backing flange weld neck, composite

weld neck flange, backing flange for inner welding neck and many others.

We, at Naysha Steel and Alloys, are major manufacturers, suppliers and dealers of various other types of weld neck pipe flanges like Raised Face weld neck flanges(RF), weld neck flat face flange(FF), Ring Type Joint (RTJ) weld neck flanges, and many such more. Please contact us for more information on more different types of weld neck flanges.

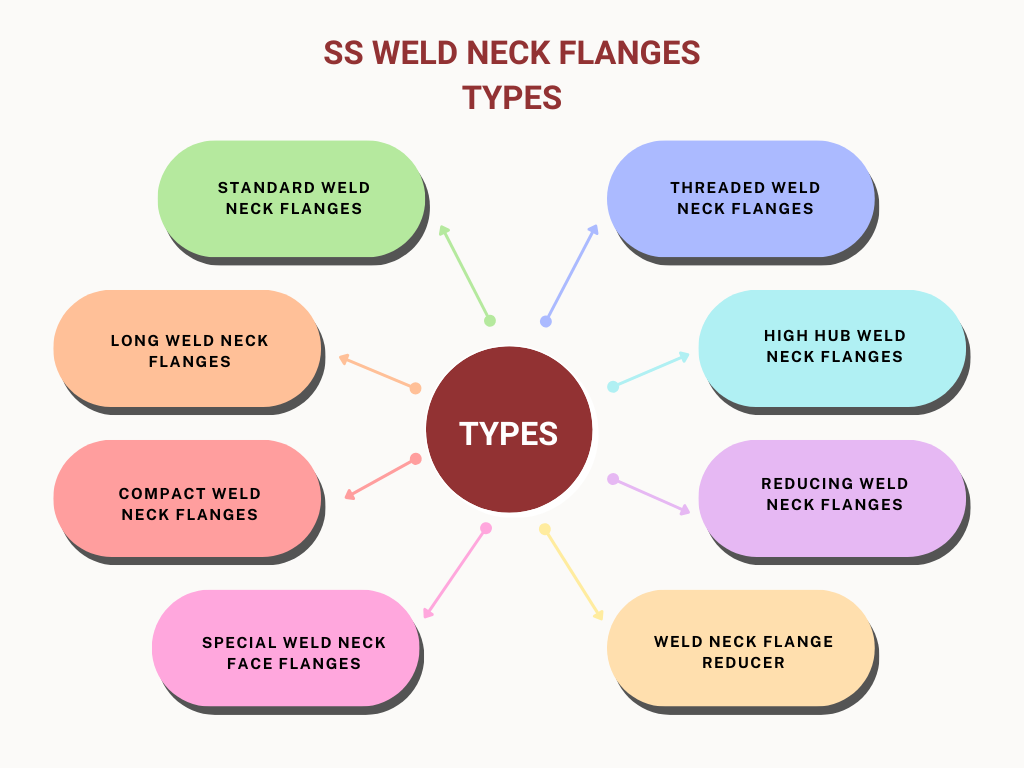

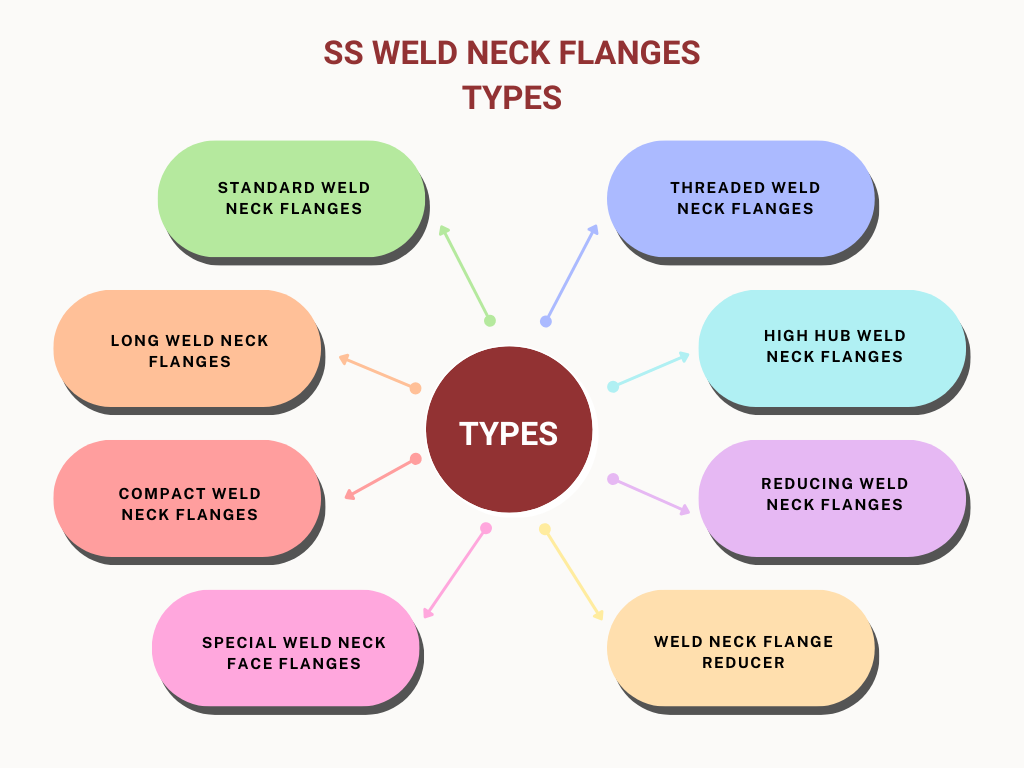

- Standard Weld Neck Flanges in Mumbai Maharashtra: These stainless steel 304h

flanges have a long tapered hub that provides strength and

support to the pipe.

- Long Weld Neck Flanges: Also known as a long radius weld neck flange, these Stainless

Steel flanges have an

long neck length.

- Compact Weld Neck Flanges: Compact weld neck flanges which are made of stainless steel

have a shorter neck length compared to

standard weld neck flanges stainless steel.

- Special Weld Neck Face Flanges in Mumbai, India: These 2 inch stainless steel

flanges have unique face structure to contain special

sealing requirements.

- Threaded Weld Neck Flanges:A threaded weld neck flange is a type of pipe fitting that is

used to contain high pressures or temperatures. It is made of stainless steel or carbon steel

and has threaded fittings that allow for easy installation and removal.

- Orifice Flanges: Stainless steel

orifice flanges made of stainless steel are specially designed for exact measurement and

control of

fluid flow rates.

- High Hub Weld Neck Flanges: These weld neck SS flanges have a larger hub

diameter compared to standard weld neck

flanges.

- Reducing Weld Neck Flanges: These weld neck flanges have different-sized openings on each

end to simplify

the connection of pipes with different diameters.

- Weld Neck Flange Reducer: A weld neck flange reducer is a type of specialty flange that

is used to join pipes of various diameters. The flange size is the larger pipe size, except for

the hole and hub size.

Get an estimate within 10 minutes!

Long Weld Neck Flange and Pipe Joint, Flange Long Weld Neck RF 300, Long Weld Neck Flange 1500, IBR

Long Weld Neck Flanges, 900 Long Weld Neck Flange, Long Weld Neck Stainless Steel Flanges, long welding neck flange asme b16.5 Manufacturer and Supplier in Mumbai, India

A long weld neck flange is a type of flange that features an extended neck, also referred to as a

hub, which is intended to transition the flange into the pipeline. The long weld neck flange length

is longer as compared to standard weld neck flanges, which provides several advantages in specific

applications. Long welding neck asme b16.5 are used in various applications including high-pressure

systems, high-temperature environments, corrosive environments, critical services and many others. The LWN flange is comprised of two parts: the upper section is a heavy-walled barrel, that ensures the strength and the stability.

Naysha Steel and Alloys is a leading company specializing in the manufacturing of long weld neck flanges. With a commitment to precision engineering and quality craftsmanship, we have established itself as a trusted provider in the industry. Committed to customer satisfaction, we, at Naysha Steel, place a strong emphasis on quality control throughout the manufacturing process. Each long weld neck flange undergoes rigorous testing to meet industry standards, ensuring durability and longevity in demanding operational environments.

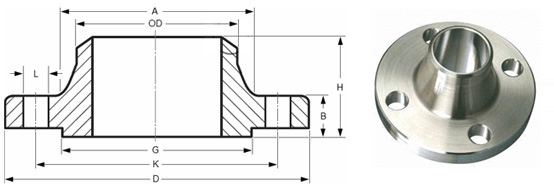

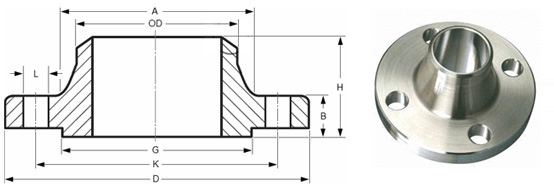

Stainless Steel Weldneck Flanges manufacturer in Mumbai: Characteristics:-

Stainless steel weld flanges possess several key characteristics like The Neck size, dia etc. Some flanges feature a Big diameter whereas some has very huge thicknesses, and some flanges differ by theri chemical properties. Below you can find the main characteritics of Stainless Steel weld neck flanges that are ready available to dispatch from Mumbai.:

-

Extended Neck: The most distinguishing feature of these flanges is their extended neck, which

allows for a smooth transition between the pipeline and the equipment being connected.

- Tapered Neck: The neck is often tapered, which helps reduce stress concentration at the weld

joint.

- Bore Size: The bore size of a long weld neck flange matches the inside diameter of the pipe,

ensuring proper alignment and flow characteristics. The long weld neck flange wall thickness is

also very much more.

- Standard Sizes: Long weld neck flanges are available in a range of standard sizes and pressure

ratings to accommodate various applications.

- Materials: There is a variety of long weld neck flange material, including carbon steel,

stainless steel, alloy steel, and other corrosion-resistant materials.

Stainless Steel Weldneck Flanges manufacturer in Mumbai: Benefits/Advantages for our Customer:-

Stainless steel weld flanges offer several advantages over other types of flange:

-

Reduced Stress: The tapered neck design reduces stress concentration at the weld joint,

improving the flange's structural integrity.

- Enhanced Strength: The extended neck provides additional strength, making them suitable for

high-pressure and high-temperature applications.

- Smooth Flow Transition: The extended neck ensures a smooth transition from the pipe to the

equipment, reducing turbulence and pressure drop.

- Better Leak Prevention: The long neck and thickness of long weld neck flanges allows for more

weld area, which improves the sealing performance and reduces the risk of leakage.

- Versatility: Long weld neck flanges can be used in a wide range of applications, making them a

versatile choice for many industries.

Naysha Steel is a leading manufacturer of Stainless Steel Long Weld Neck Flanges in Mumbai, India.

With years of experience and expertise, we are renowned as a dependable name in the industry. We, at

Naysha Steel are known for delivering highest-quality long weld neck flanges for sale that follow

the international standards, european standard for long weld neck flanges. We also manufacture and

supply gasket for weld neck flange. Naysha Steel prides itself in being an state-of-the-art

manufacturer, which enables us to produce long weld neck flanges of premium quality. Along with

being that, we are also first grade long weld neck flange distributors in the market. We are

committed to providing A-1 customer service, perfect delivery and reasonable pricing, making us the

first choice for stainless steel long neck weld flange manufacturer in Mumbai, India. We also are

UNS S32205 weld neck flanges, rfwn flange, that is raised face weld neck flange manufacturer in India.

Features of 24 600 RFWN 500 A105, IBR Weld Neck Flanges, Flange Welding Neck 150, Welding Neck

Flanges DIN 2633, Long Weld Neck Flange Class 300, Weld Neck Flanges B16.5, SS Weld Neck Flanges manufacturer in Mumbai

- High strength and durability due to the use of stainless steel alloys in making

weld neck flanges.

- Excellent resistance to corrosion, oxidation, and high temperatures of these

stainless steel flanges.

- Leak-resistant design of these flanges with a secure and tight seal.

- Strong structure of weld neck flanges with a long tapered hub for added support and reduced

stress concentrations.

- Easy alignment during installation, ensuring proper pipe alignment.

- Smooth transition from the flange neck to the pipe bore, promoting effective fluid flow and

minimum

pressure drop.

- These weld neck flanges are suitable for high-pressure and high-temperature applications.

- The stainless steel flange

price, specially weld neck flange prices like weld neck flange 850 nb price and rest of

the others are quite reasonable and can easily fit in your budget.

Size of

Stainless Steel Weld Neck Flanges

| Nominal Size |

Outside Diameter

(OD) |

Min. Thickness

(T) |

RF Dia.

(R) |

No. of Bolt Holes |

Diameter of Holes |

Bolt Circle

(BC) |

SO Bore ID

(SB) |

WN Bore ID

(WB) |

Dia. Hub Base

(HB) |

Dia. of Hub Top

(HT) |

SO LTH

(SL) |

WN LTH

(WL) |

| 1⁄2 |

3.50 |

0.38 |

1.38 |

4 |

0.62 |

2.38 |

0.88 |

0.62 |

1.19 |

0.84 |

0.56 |

1.81 |

| 3⁄4 |

3.88 |

0.44 |

1.69 |

4 |

0.62 |

2.75 |

1.09 |

0.82 |

1.50 |

1.05 |

0.56 |

2.00 |

| 1 |

4.25 |

0.50 |

2.00 |

4 |

0.62 |

3.12 |

1.36 |

1.05 |

1.94 |

1.32 |

0.62 |

2.12 |

| 11⁄4 |

4.62 |

0.56 |

2.50 |

4 |

0.62 |

3.50 |

1.70 |

1.38 |

2.31 |

1.66 |

0.75 |

2.19 |

| 11⁄2 |

5.00 |

0.62 |

2.88 |

4 |

0.62 |

3.88 |

1.95 |

1.61 |

2.56 |

1.90 |

0.81 |

2.38 |

| 2 |

6.00 |

0.69 |

3.62 |

4 |

0.75 |

4.75 |

2.44 |

2.07 |

3.06 |

2.38 |

0.94 |

2.44 |

| 21⁄2 |

7.00 |

0.81 |

4.12 |

4 |

0.75 |

5.50 |

2.94 |

2.47 |

3.56 |

2.88 |

1.06 |

2.69 |

| 3 |

7.50 |

0.88 |

5.00 |

4 |

0.75 |

6.00 |

3.57 |

3.07 |

4.25 |

3.50 |

1.12 |

2.69 |

| 31⁄2 |

8.50 |

0.88 |

5.50 |

8 |

0.75 |

7.00 |

4.07 |

3.55 |

4.81 |

4.00 |

1.19 |

2.75 |

| 4 |

9.00 |

0.88 |

6.19 |

8 |

0.75 |

7.50 |

4.57 |

4.03 |

5.31 |

4.50 |

1.25 |

2.94 |

| 5 |

10.00 |

0.88 |

7.31 |

8 |

0.88 |

8.50 |

5.66 |

5.05 |

6.44 |

5.56 |

1.38 |

3.44 |

| 6 |

11.00 |

0.94 |

8.50 |

8 |

0.88 |

9.50 |

6.72 |

6.07 |

7.56 |

6.63 |

1.50 |

3.44 |

| 8 |

13.50 |

1.06 |

10.62 |

8 |

0.88 |

11.75 |

8.72 |

7.98 |

9.69 |

8.63 |

1.69 |

3.94 |

| 10 |

16.00 |

1.12 |

12.75 |

12 |

1.00 |

14.25 |

10.88 |

10.02 |

12.00 |

10.75 |

1.88 |

3.94 |

| 12 |

19.00 |

1.19 |

15.00 |

12 |

1.00 |

17.00 |

12.88 |

12.00 |

14.38 |

12.75 |

2.12 |

4.44 |

| 14 |

21.00 |

1.31 |

16.25 |

12 |

1.12 |

18.75 |

14.14 |

13.25 |

15.75 |

14.00 |

2.19 |

4.94 |

| 16 |

23.50 |

1.38 |

18.50 |

16 |

1.12 |

21.25 |

16.16 |

15.25 |

18.00 |

16.00 |

2.44 |

4.94 |

| 18 |

25.00 |

1.50 |

21.00 |

16 |

1.25 |

22.75 |

18.18 |

17.25 |

19.88 |

18.00 |

2.62 |

5.44 |

| 20 |

27.50 |

1.62 |

23.00 |

20 |

1.25 |

25.00 |

20.20 |

19.25 |

22.00 |

20.00 |

2.81 |

5.62 |

| 22 |

29.50 |

1.75 |

25.25 |

20 |

1.38 |

27.25 |

22.22 |

21.25 |

24.25 |

22.00 |

3.07 |

5.82 |

| 24 |

32.00 |

1.81 |

27.25 |

20 |

1.38 |

29.50 |

24.25 |

23.25 |

26.12 |

24.00 |

3.19 |

5.94 |

Naysha Steel and Alloys is an ISO certified SS Weld Neck Flange Manufacturers &

distributor in Mumbai, India

We, Naysha Steels and Alloys, are a manufacturer supplier Stainless Steel Weld Neck Flange

offering in all Ratings up to 2500#, built a distribution network with more then 65 countries

globally. Naysha Steel and Alloys, our distinguished name in the industry, proudly holds ISO certification and stands as a prominent manufacturer and distributor of stainless steel weld neck flanges in India. Specializing in high-quality products, Naysha Steel and Alloys adhere to stringent manufacturing standards to meet the requirements of diverse industrial applications. We have an extensive distribution network across India ensures timely and efficient delivery of stainless steel weld neck flanges to customers nationwide. Our company's customer-centric approach positions it as a reliable partner for those seeking top-tier products in the stainless steel flange industry. Whether for high-pressure applications or critical fluid handling, we, at Naysha Steel and Alloys stand out as a trusted source for ISO-certified stainless steel weld neck flanges, contributing to the success and reliability of various industrial projects across India.

Stainless Steel Weldneck Flanges manufacturer in Mumbai: Dimensions:-

We have an rich variety of stainless weld neck flange with many sizes and dimensions like 2 1/2" weld neck flange, 4" weld neck flange, 3" weld neck flange, 6" weld neck flange, 2" weld neck flange, 8 inch weld neck flange, 12" weld neck flange, 10" weld neck flange, wnrf flange 150#, wnrf flange 300#

| ANSI/ASME/ASA B16.5 300lb/sq.in. Flange

WN-RF |

| ø |

D |

b |

g |

m |

a |

J* |

h |

k |

Holes |

l |

Kg. |

| 1/2" |

88,9 |

11,1 |

34,9 |

30,2 |

21,3 |

15,7 |

47,6 |

60,3 |

4 |

15,9 |

0,500 |

| 3/4" |

98,4 |

12,7 |

42,9 |

38,1 |

26,7 |

20,8 |

52,4 |

69,8 |

4 |

15,9 |

0,700 |

| 1" |

107,9 |

14,3 |

50,8 |

49,2 |

33,5 |

26,7 |

55,6 |

79,4 |

4 |

15,9 |

1,100 |

| 1 1/4" |

117,5 |

15,9 |

63,5 |

58,8 |

42,2 |

35,1 |

57,1 |

88,9 |

4 |

15,9 |

1,500 |

| 1 1/2" |

127,0 |

17,5 |

73,0 |

65,1 |

48,3 |

40,9 |

61,9 |

98,4 |

4 |

15,9 |

1,800 |

| 2" |

152,4 |

19,0 |

92,1 |

77,8 |

60,3 |

52,6 |

63,5 |

120,6 |

4 |

19,0 |

2,700 |

| 2 1/2" |

177,8 |

22,2 |

104,8 |

90,5 |

73,1 |

62,7 |

69,8 |

139,7 |

4 |

19,0 |

4,400 |

| 3" |

190,5 |

23,8 |

127,0 |

107,9 |

88,9 |

78,0 |

69,8 |

152,4 |

4 |

19,0 |

5,200 |

| 3 1/2" |

215,9 |

23,8 |

139,7 |

122,2 |

101,6 |

90,2 |

71,4 |

177,8 |

8 |

19,0 |

6,400 |

| 4" |

228,6 |

23,8 |

157,2 |

134,9 |

114,3 |

102,4 |

76,2 |

190,5 |

8 |

19,0 |

7,500 |

| 5" |

254,0 |

23,8 |

185,7 |

163,5 |

141,2 |

128,3 |

88,9 |

215,9 |

8 |

22,2 |

9,200 |

| 6" |

279,4 |

25,4 |

215,9 |

192,1 |

168,4 |

154,2 |

88,9 |

241,3 |

8 |

22,2 |

11,000 |

| 8" |

342,9 |

28,6 |

269,9 |

246,1 |

219,1 |

202,7 |

101,6 |

298,4 |

8 |

22,2 |

18,300 |

| 10" |

406,4 |

30,2 |

323,8 |

304,8 |

273,0 |

254,5 |

101,6 |

361,9 |

12 |

25,4 |

25,000 |

| 12" |

482,6 |

31,7 |

381,0 |

365,1 |

323,8 |

304,8 |

114,3 |

431,8 |

12 |

25,4 |

39,000 |

| 14" |

533,4 |

34,9 |

412,7 |

400,0 |

355,6 |

336,5 |

127,0 |

476,2 |

12 |

28,6 |

51,000 |

| 16" |

596,9 |

36,5 |

469,9 |

457,2 |

406,4 |

387,3 |

127,0 |

539,7 |

16 |

28,6 |

60,000 |

| 18" |

635,0 |

39,7 |

533,4 |

504,8 |

457,2 |

438,1 |

139,7 |

577,8 |

16 |

31,7 |

71,000 |

| 20" |

698,5 |

42,9 |

584,2 |

558,8 |

508,0 |

488,9 |

144,5 |

635,0 |

20 |

31,7 |

88,000 |

| 22" |

749,3 |

46,0 |

641,2 |

609,6 |

558,8 |

539,7 |

149,2 |

692,1 |

20 |

34,9 |

102,000 |

| 24" |

812,8 |

47,6 |

692,1 |

663,6 |

609,6 |

590,5 |

152,4 |

749,3 |

20 |

34,9 |

119,000 |

| * |

The data "J" corresponds to the STD schedule

|

| ANSI/ASME/ASA B16.5 300lb/sq.in. Flange

WN-RF |

| ø |

D |

b |

g |

m |

a |

J* |

h |

k |

Holes |

l |

Kg. |

| 1/2" |

95,2 |

14,3 |

34,9 |

38,1 |

21,3 |

15,7 |

52,4 |

66,7 |

4 |

15,9 |

0,900 |

| 3/4" |

117,5 |

15,9 |

42,9 |

47,6 |

26,7 |

20,8 |

57,1 |

82,5 |

4 |

19,0 |

1,500 |

| 1" |

123,8 |

17,5 |

50,8 |

54,0 |

33,5 |

26,7 |

61,9 |

88,9 |

4 |

19,0 |

1,900 |

| 1 1/4" |

133,3 |

19,0 |

63,5 |

63,5 |

42,2 |

35,1 |

65,1 |

98,4 |

4 |

19,0 |

2,600 |

| 1 1/2" |

155,6 |

20,6 |

73,0 |

69,8 |

48,3 |

40,9 |

68,3 |

114,3 |

4 |

22,2 |

3,300 |

| 2" |

165,1 |

22,2 |

92,1 |

84,1 |

60,3 |

52,6 |

69,8 |

127,0 |

8 |

19,0 |

3,600 |

| 2 1/2" |

190,5 |

25,4 |

104,8 |

100,0 |

73,1 |

62,7 |

76,2 |

149,2 |

8 |

22,2 |

5,400 |

| 3" |

209,5 |

28,6 |

127,0 |

117,5 |

88,9 |

78,0 |

79,4 |

168,3 |

8 |

22,2 |

7,400 |

| 3 1/2" |

228,6 |

30,2 |

139,7 |

133,3 |

101,6 |

90,2 |

81,0 |

184,1 |

8 |

22,2 |

8,900 |

| 4" |

254,0 |

31,7 |

157,2 |

146,0 |

114,3 |

102,4 |

85,7 |

200,0 |

8 |

22,2 |

11,900 |

| 5" |

279,4 |

34,9 |

185,7 |

177,8 |

141,2 |

128,3 |

98,4 |

234,9 |

8 |

22,2 |

16,000 |

| 6" |

317,5 |

36,5 |

215,9 |

206,4 |

168,4 |

154,2 |

98,4 |

269,9 |

12 |

22,2 |

20,200 |

| 8" |

381,0 |

41,3 |

269,9 |

260,3 |

219,1 |

202,7 |

111,1 |

330,2 |

12 |

25,4 |

31,000 |

| 10" |

444,5 |

47,6 |

323,4 |

320,7 |

273,0 |

254,5 |

117,5 |

387,3 |

16 |

28,6 |

44,300 |

| 12" |

520,7 |

50,8 |

381,0 |

374,6 |

323,8 |

304,8 |

130,2 |

450,8 |

16 |

31,7 |

64,000 |

| 14" |

584,2 |

54,0 |

412,7 |

425,4 |

355,6 |

336,5 |

142,9 |

514,3 |

20 |

31,7 |

88,000 |

| 16" |

647,7 |

57,1 |

469,9 |

482,6 |

406,4 |

387,3 |

146,0 |

571,5 |

20 |

34,9 |

113,000 |

| 18" |

711,2 |

60,3 |

533,4 |

533,4 |

457,2 |

438,1 |

158,7 |

628,6 |

24 |

34,9 |

134,000 |

| 20" |

774,7 |

63,5 |

584,2 |

587,4 |

508,0 |

488,9 |

161,9 |

685,8 |

24 |

34,9 |

171,000 |

| 22" |

838,2 |

66,7 |

641,2 |

641,2 |

558,8 |

539,7 |

165,1 |

742,9 |

24 |

41,3 |

195,000 |

| 24" |

914,4 |

69,8 |

692,1 |

701,7 |

609,6 |

590,5 |

168,3 |

812,8 |

24 |

41,3 |

238,000 |

| * |

The data "J" corresponds to the STD schedule

|

| ANSI/ASME/ASA B16.5 600lb/sq.in. Flange

WN-RF |

| ø |

D |

b |

g |

m |

J |

h |

k |

Holes |

l |

Kg. |

| 1/2" |

95,2 |

14,3 |

34,9 |

38,1 |

22,3 |

22,2 |

66,7 |

4 |

15,9 |

0,800 |

| 3/4" |

117,5 |

15,9 |

42,9 |

47,6 |

27,7 |

25,4 |

82,5 |

4 |

19,0 |

1,400 |

| 1" |

123,8 |

17,5 |

50,8 |

54,0 |

34,5 |

27,0 |

88,9 |

4 |

19,0 |

1,600 |

| 1 1/4" |

133,3 |

20,6 |

63,5 |

63,5 |

43,2 |

28,6 |

98,4 |

4 |

19,0 |

2,100 |

| 1 1/2" |

155,6 |

22,2 |

73,0 |

69,8 |

49,5 |

31,7 |

114,3 |

4 |

22,2 |

3,100 |

| 2" |

165,1 |

25,4 |

92,1 |

84,1 |

62,0 |

36,5 |

127,0 |

8 |

19,0 |

3,700 |

| 2 1/2" |

190,5 |

28,6 |

104,8 |

100,0 |

74,7 |

41,3 |

149,2 |

8 |

22,2 |

5,400 |

| 3" |

209,5 |

31,7 |

127,0 |

117,5 |

90,7 |

46,0 |

168,3 |

8 |

22,2 |

7,300 |

| 3 1/2" |

228,6 |

34,9 |

139,7 |

133,3 |

103,4 |

49,2 |

184,1 |

8 |

25,4 |

8,900 |

| 4" |

273,0 |

38,1 |

157,2 |

152,4 |

116,1 |

54,0 |

215,9 |

8 |

25,4 |

11,800 |

| 5" |

330,2 |

44,4 |

185,7 |

188,9 |

143,8 |

60,3 |

266,7 |

8 |

28,6 |

24,500 |

| 6" |

355,6 |

47,6 |

215,9 |

222,2 |

170,7 |

66,7 |

292,1 |

12 |

28,6 |

29,500 |

| 8" |

419,1 |

55,6 |

269,9 |

273,0 |

221,5 |

76,2 |

349,2 |

12 |

31,7 |

43,000 |

| 10" |

508,0 |

63,5 |

323,8 |

342,8 |

276,3 |

85,7 |

431,8 |

16 |

34,9 |

70,000 |

| 12" |

558,8 |

66,7 |

381,0 |

400,0 |

327,1 |

92,1 |

488,9 |

20 |

34,9 |

86,000 |

| 14" |

603,2 |

69,8 |

412,7 |

431,8 |

359,1 |

93,7 |

527,0 |

20 |

38,1 |

100,000 |

| 16" |

685,8 |

76,2 |

469,9 |

495,3 |

410,5 |

106,4 |

603,2 |

20 |

41,3 |

142,000 |

| 18" |

742,9 |

82,5 |

533,4 |

546,1 |

461,8 |

117,5 |

654,0 |

20 |

44,4 |

175,000 |

| 20" |

812,8 |

88,9 |

584,2 |

609,6 |

513,1 |

127,0 |

723,9 |

24 |

44,4 |

232,000 |

| 22" |

869,9 |

95,2 |

641,2 |

666,7 |

564,4 |

133,3 |

777,9 |

24 |

47,6 |

292,000 |

| 24" |

939,8 |

101,6 |

692,1 |

717,5 |

615,9 |

139,7 |

838,2 |

24 |

50,8 |

330,000 |

Uses of Flange Welding Neck ANSI 150, 24 600 RFWN 500 A105, 36 Class 125 Weld Neck Flange, 150

Pounds Weld Neck Flange, Weld Neck Flange ANSI B16 5, Weld Neck SS Flanges

Stainless steel weld

neck flanges are widely used in industries where trusted and leak-free connections are

necessary. These applications of weld neck flanges are in high-pressure and high-temperature

conditions

because of their powerful construction and secure welding. These stainless steel 316l

flanges are commonly used in the oil and gas industry, where they ease the connection of

pipes, valves, and equipment in oil refineries, pipelines, and offshore platforms. In the

petrochemical industry, stainless steel weld neck flanges uses are for connecting process

vessels, pumps, and heat exchangers.

Quality of Flange Welding Neck 150, Weld Neck Flanges Flat Face ASME, M.S Weld Neck Flange ND16,

ANSI Weld Neck Flange FF, Weld Neck Flanges Stainless Steel

Tough quality control processes are implemented by Naysha Steel throughout the manufacturing and

supplying process of these stainless steel weld neck flanges. This includes precise cutting,

shaping, and welding techniques to achieve proper dimensions and strong weld joints. Detailed

inspections are conducted by Naysha Steel to identify any defects or imperfections and ensure

adherence to the required standards. Secondly, stainless steel weld neck flanges undergo extensive

testing procedures to verify their quality.

Get an estimate within 10 minutes!

Flange Welding Neck ANSI 150, IS6392 Weld Neck Flanges, Weld Neck Stainless Steel Flanges

Manufacturer India, UNS S31803 Weld Neck Flanges Stockist, UNS S31803 Weld Neck Flanges Manufacturers, UNS

S31803 Weld Neck Flanges Exporter, UNS S32205 Weld Neck Flanges Stockist : Grades & Classes

- ASTM A182 F304/F304L: Standard austenitic stainless steel grade.

- ASTM A182 F316/F316L: Austenitic stainless steel with enhanced corrosion

resistance.

- ASTM A182 F321/F321H: Stabilized stainless steel grade with titanium addition.

- ASTM A182 F347/F347H: Stabilized stainless steel grade with niobium addition.

- ASTM A182 F51: Duplex stainless steel grade with high strength and corrosion resistance.

- ASTM A182 F53: Super duplex stainless steel grade with excellent corrosion resistance.

- Class 125: Class 125 Weld Neck Flange suitable for aggressive conditions.

- Class 150: Weld neck flange design for low-pressure applications.

- Class 300: Flanges suitable for moderate-pressure applications.

- Class 600: Weld Neck Flange Class 600 designed for high-pressure applications.

- Class 900: Flanges suitable for very high-pressure applications.

- Class 1500: Flanges designed for extremely high-pressure applications.

Flange Welding Neck 150, 18 300 Class SCH 80 Weld Neck Flange, Class 150 Weld Neck Flange SCH 80,

Welding Neck Flanges SCH 40, SS Weld Neck Flanges Specifications

| Specification Of : |

Weld Neck Stainless Steel Flanges |

| JIS Standards |

5K, 10K, 40K, 16K 20K 30K, 63K |

| Size Of Bore Diameter Flange |

NPS ≤ 10 |

| Manufacturer Of Standard Dimensions |

EN-1092 Flange, ASME B16.48 Flange, API605 Flange, BS4504 Flange, EN1092 Flange, UNI

Flange, ISO Flange, API7S-43 Flange, ANSI/ASME B16.5 Flange, API7S-15 Flange, MSS S44

Flange, IS 2062 Flange, ASME B16.36 Flange, DIN Flange, AWWA C207 Flange, B16.47 Series

A & B Flange, BS1560-3.1 Flange, ISO70051 Flange, API Flange, ASME Code for 12 inche

Welding Neck Flanges.

|

| Minimum Pressure |

150# To 2500# |

| Flange Face Type |

Raised Face, Groove And Small Tongue Groove, RTJ, Weld Neck Flanges Flat Face, Large

Tongue & Large

Male-Female And Small Male-Female, Lap-Joint Face. |

| Top Six Type Of Flanges |

Threaded, Lap Joint, Socket-Weld, Blind, Slip-On or Weld Neck Flanges

|

| Standard Materials |

Duplex Steel & Super Duplex Steel, Copper Nickel, Wrought Iron, Inconel, Mild Steel,

Stainless Steel, Hastelloy, Cast Iron, Alloy Steel, Carbon Steel.

|

| Thickness Length |

NPS ≤ 18

|

| Welding neck flanges size |

(1/2") To (48")

|

| Manufacturing Process |

Forged/ Machined/ Heat Treated

|

| Other Type Of Flange |

Forged/ Plate/ Threaded

|

| Application |

Oil And Gas Industry

Power Plants Industry

Food Processing And Manufacturing

Waterworks Systems

Fossil Fuel Power Plants

Nuclear Power Application

Municipal Pipe Systems

|

Please find below our manufacturing and Sales network below: (Contact us for detailed information for your nearest branches)

- Stainless Steel Weld Neck Flanges manufacturer and contractor in Hyderabad

- Stainless Steel Weld Neck Flanges manufacturer and supplier in Chennai

- Stainless Steel Weld Neck Flanges manufacturer and stockists in Pune

- Stainless Steel Weld Neck Flanges manufacturer and dealer in Faridabad

- Stainless Steel Weld Neck Flanges manufacturer and warehousing in Chandigarh

- Stainless Steel Weld Neck Flanges manufacturer and wholesalor in Delhi

- Stainless Steel Weld Neck Flanges manufacturer and trader in Coimbatore

- Stainless Steel Weld Neck Flanges manufacturer and stockholder in Bangalore

Frequently Asked Questions

What is a stainless steel weldneck flange?

A stainless steel weldneck flange is a type of pipe flange designed to be welded onto the

neck of a pipe. It provides a smooth, high-strength connection for joining pipes, valves,

and other equipment.

What types of stainless steel are typically used for weldneck flanges?

Common stainless steel materials include 304, 316, and 321, among others. The choice of

stainless steel grade depends on the specific application and the required corrosion

resistance.

What sizes are available for stainless steel weldneck flanges?

Stainless steel weldneck flanges are available in a wide range of sizes, typically ranging

from 1/2 inch to several feet in diameter. The size you need depends on your specific piping

system requirements.

Can stainless steel weldneck flanges be used with non-stainless steel pipes?

Yes, stainless steel weldneck flanges can be used with pipes made of other materials,

provided the flange material is compatible with the pipe material, and the connection is

properly sealed.

We Have Provided Various Dimensions, Tolerances And Schedule Charts in our Weight Chart Page

Prepared with Precision And Accuracy

| ss 6 inch weld neck flange dimensions |

28" ss weld neck flange dimension |

| ansi b16.47 weld neck flange dimensions pdf |

30" 300# weld neck flange dimensions |

| 18 300 weld neck flange dimention |

28 weld neck flange dimension |

| 18" 300# weld neck flange dimention schedule 80 |

150# class weld neck flange dimensions in mm |

| 18" 300# weld neck flange dimension schedule 80 |

2 inches weld neck flange dimension |

| 900# long weld neck flange dimensions |

30" 150# weld neck flange dimensions |

| long weld neck flange tolerance |

long weld neck flange weights |

| long weld neck flange catalogue |

din pn10 weld neck flange dimensions |

| schedule 80 weld neck flange dimensions |

m.s weld neck flange nd16 dimension idf |

| class 1500 weld neck flange dimensions in mm |

dn80 weld neck flange dimensions |

| m.s weld neck flange nd16 dimension |

heavy barrel long weld neck flange dimensions |

| inch dia of weld neck flange |

long weld neck flange dimensions metric |

| npt weld neck flange standard |

class 900 weld neck flange dimensions in mm |

| pn25 weld neck flange dimensions |

long weld neck rtj flange dimensions |

| long weld neck flange schedule chart |

welding neck flanges weight |

| weld neck flanges dimensions ansi |

weld neck flange dimension chart wit bore |

| weld neck flange b16.5 dimensions |

weld neck flange dimensions pn10 |

| weld neck flange pn16 |

150# weld neck flange |

The above mentioned weld neck flange nomenclature is specified in complete details with 100% accuracy

is given in weight chart page. This page also contains information on

thickness of 4 nb 300 pound rating weld neck flange, thickness of 6 nb 150 pound rating weld neck

flange and various such thickness and specifications. Also, we have added the heavy barrel weld neck

flange specifications to the page. Along with that we have special features like long weld neck

flanges weight calculator and many more available. We also have the fully updated weld neck flange price list with us for your reference.

Industries served by Stainless Steel Weld Neck Flanges

In the oil and gas industry, blind Alloy Steel flanges are used in pipelines, storage tanks, and offshore platforms. They are employed for closing off openings during maintenance, repair, or when a branch connection is not required. Petrochemical plants utilize blind Alloy Steel flanges in equipment such as reactors, distillation columns, and storage vessels. These flanges provide a secure and leak-proof seal when closing off unused openings or isolating sections of the process.

Oil and Gas Industries

The oil and gas industry includes a wide range of from drilling and

production to refining and marketing. Some of the major players in this

include oil and gas companies, service providers, equipment.

Petroleum Industries

In the drilling process, stainless steel is used to make drill bits, pipes, and other

equipment that must withstand high pressures and temperatures. Stainless steel is

also used to make pumps, valves, and fittings for the transportation.

Shipbuilding in India

In storage applications, stainless steel is used to make tanks and containers that

can safely store corrosive and hazardous chemicals. It is also used in piping

systems for chemical transfer and distribution chemical industry.

Marking & Pricing

Products are packaged to ensure that there is no damage during of goods transport. In case of exports, standard export packaging is done with utmost care in wooden covering or boxing. All products are marked with Grade, Lot No, Size, Degree and our trade mark. On special requests we can also, make

customized marking on our products.

Quality Assurance

At Naysha Steel, all fittings and flanges are subject to strict inspection at each and every stage of the production process, from starting material

purchasing to product dispatch. They are visually examined for compliance to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards.

Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality compliance

of products.

Test Certificates: Manufacturer Test Certificate as per EN 10204 / 3.1B Raw Materials Certificate, 100% Radiography Test Report, Third

Party Inspection Report