Stainless Steel SS 316 400 Class Flanges Manufacturer And Supplier In Mumbai, India

Nayaha Steel & Alloy in Mumbai India is the reputed manufacturer of top-quality Stainless Steel 316 class of flanges from SS 400. The reputation for our everlasting high quality and expert precision engineering allows us to tend to all industrial demands in a perfect way. The stainless steel grade 316 400 Class Flanges provided by us is known for its exceptional characteristics. This includes toughness, corrosion resistance, and strong construction, which are suitable for demanding operations across a wide range of industries. Whether it is the latest innovative technology or the world-class manufacturing plants, we have it all as well as an incredibly skilled labor force, safeguarding the high quality of our products complying with international standards. Naysha Steel and Alloy puts great emphasis on customer satisfaction. With a wide range of reliable products, delivery on time, and competitive pricing we ensure full customer satisfaction providing high-quality services. Rely on us for all your stainless steel flange needs, and enjoy the ultimate in quality and service.

SS 316 400 Class Flanges Manufacturer And Supplier In Mumbai, India

Naysha Steel Alloy, which is well-known as a company and a producer and distributor in the industry, markets SS 316 400 Class Flanges in Mumbai, India. We are known for our high quality and utmost reliability and offer a wide range of flanges manufactured from the best stainless-steel 316, offering resistance and long-term durability. We have advanced manufacturing plants equipped with a high professional staff and produce products that are precise and meet global standards for the industrial needs. Our principles that include quality, quickness and price competitiveness is what makes us the preferable option for anyone looking for high caliber flange solutions in and around Mumbai.

Countless Benefits of SS 316 400 Class Flanges, 400# SS 316 Flange:

The SS 316 400 Class Flanges are associated with so many advantages as same to the other types of flanges. Take a look for the key benefits of stainless steel weld neck flanges.

-

Easy Installation: The simple design of the SS 316 400 Class Flanges intuitively reduces mounting time with standardized parameters and push-on bolt connection. This results in less time and money consumption.

-

Leak-Proof Design: Due to precision engineering we can reduce leaks and time for the repairing of them, also get rid of need for a closer monitoring, which, as a result, gives you much less money for the maintenance.

-

Corrosion Resistance: The low temperature piping typically made of SS 316 400 Class Flanges, a weathertight, high-quality stainless steel resistant to chemical corrosion, can last for years to come and help ensure system efficiency.

-

High Strength: And, the flanges with the highest impact resistance gives structural integrity and lengthy service life under high pressure operation environment and makes sure of safety, long-lasting and quality performance

-

Wide Range of Applications: Having a solid grounding in a number of environments, 400 Class Flanges SS 316 are adopted in industrial and commercial situations, like petrochemical companies and food production plants, and they prove their high-performance quality over and over again.

SS 316 400 Class Flanges, 400 Class Flanges, SS 316 400# Flanges, Stainless Steel 316 Flanges, Manufacturer And Supplier In Mumbai, India

Naysha Steel and Alloy is a leading SS 316 400 Class Flange production manufacturer and supplier in Mumbai, India, and global clients. Through the high-quality and accurate work, we display on our wide range of 400 Class Flanges mill the precious grade stainless steel 316. SS 316 400# Flanges that we manufacture were developed to perform at the highest levels of durability, corrosion resistance, and operation capability and that's why they are utilized for many critical applications in chemical processing, petroleum industry, pharmaceuticals, and others at the same time. These flanges can be operated close to the exhaust temperature or in the furnace itself, these flanges are designed to withstand extreme temperatures and pressures.

We highly believe that customers are our main asset and we always try to do out best to meet their needs and provide services that exceed competition. Our team of experienced professionals masters the utilization of advanced manufacturing techniques and meticulous quality control standards that provide every flange with a high quality similar to international standards. We were able to be true to our mission and to provide you with solutions tailored to specific project needs when you chose us – a company, which prevails on the industry. Customers are rest assured of quality, timeliness and cost-effective solutions of 316 400 Class Flanges, Naysha Steel and Alloy, a leading supplier of material, offers. Reach out to us today to determine your needs in flanges and experience the effect of collaboration with a trusted partner in stainless solid.

Stainless Steel 316 400 Class Flanges, SS 316 400 Class Flanges Size In Mumbai, India shop:

| Nominal Size |

Outside Diameter(OD) |

Min. Thickness(T) |

RF Dia.(R) |

No. of Bolt Holes |

Diameter of Holes |

Bolt Circle(BC) |

SO Bore ID(SB) |

WN Bore ID(WB) |

Dia. Hub Base(HB) |

Dia. of Hub Top(HT) |

SO LTH(SL) |

WN LTH(WL) |

| 1⁄2 |

3.50 |

0.38 |

1.38 |

4 |

0.62 |

2.38 |

0.88 |

0.62 |

1.19 |

0.84 |

0.56 |

1.81 |

| 3⁄4 |

3.88 |

0.44 |

1.69 |

4 |

0.62 |

2.75 |

1.09 |

0.82 |

1.50 |

1.05 |

0.56 |

2.00 |

| 1 |

4.25 |

0.50 |

2.00 |

4 |

0.62 |

3.12 |

1.36 |

1.05 |

1.94 |

1.32 |

0.62 |

2.12 |

| 11⁄4 |

4.62 |

0.56 |

2.50 |

4 |

0.62 |

3.50 |

1.70 |

1.38 |

2.31 |

1.66 |

0.75 |

2.19 |

| 11⁄2 |

5.00 |

0.62 |

2.88 |

4 |

0.62 |

3.88 |

1.95 |

1.61 |

2.56 |

1.90 |

0.81 |

2.38 |

| 2 |

6.00 |

0.69 |

3.62 |

4 |

0.75 |

4.75 |

2.44 |

2.07 |

3.06 |

2.38 |

0.94 |

2.44 |

| 21⁄2 |

7.00 |

0.81 |

4.12 |

4 |

0.75 |

5.50 |

2.94 |

2.47 |

3.56 |

2.88 |

1.06 |

2.69 |

| 3 |

7.50 |

0.88 |

5.00 |

4 |

0.75 |

6.00 |

3.57 |

3.07 |

4.25 |

3.50 |

1.12 |

2.69 |

| 31⁄2 |

8.50 |

0.88 |

5.50 |

8 |

0.75 |

7.00 |

4.07 |

3.55 |

4.81 |

4.00 |

1.19 |

2.75 |

| 4 |

9.00 |

0.88 |

6.19 |

8 |

0.75 |

7.50 |

4.57 |

4.03 |

5.31 |

4.50 |

1.25 |

2.94 |

| 5 |

10.00 |

0.88 |

7.31 |

8 |

0.88 |

8.50 |

5.66 |

5.05 |

6.44 |

5.56 |

1.38 |

3.44 |

| 6 |

11.00 |

0.94 |

8.50 |

8 |

0.88 |

9.50 |

6.72 |

6.07 |

7.56 |

6.63 |

1.50 |

3.44 |

| 8 |

13.50 |

1.06 |

10.62 |

8 |

0.88 |

11.75 |

8.72 |

7.98 |

9.69 |

8.63 |

1.69 |

3.94 |

| 10 |

16.00 |

1.12 |

12.75 |

12 |

1.00 |

14.25 |

10.88 |

10.02 |

12.00 |

10.75 |

1.88 |

3.94 |

| 12 |

19.00 |

1.19 |

15.00 |

12 |

1.00 |

17.00 |

12.88 |

12.00 |

14.38 |

12.75 |

2.12 |

4.44 |

| 14 |

21.00 |

1.31 |

16.25 |

12 |

1.12 |

18.75 |

14.14 |

13.25 |

15.75 |

14.00 |

2.19 |

4.94 |

| 16 |

23.50 |

1.38 |

18.50 |

16 |

1.12 |

21.25 |

16.16 |

15.25 |

18.00 |

16.00 |

2.44 |

4.94 |

| 18 |

25.00 |

1.50 |

21.00 |

16 |

1.25 |

22.75 |

18.18 |

17.25 |

19.88 |

18.00 |

2.62 |

5.44 |

| 20 |

27.50 |

1.62 |

23.00 |

20 |

1.25 |

25.00 |

20.20 |

19.25 |

22.00 |

20.00 |

2.81 |

5.62 |

| 22 |

29.50 |

1.75 |

25.25 |

20 |

1.38 |

27.25 |

22.22 |

21.25 |

24.25 |

22.00 |

3.07 |

5.82 |

| 24 |

32.00 |

1.81 |

27.25 |

20 |

1.38 |

29.50 |

24.25 |

23.25 |

26.12 |

24.00 |

3.19 |

5.94 |

Stainless Steel 316, ANSI Class 400 Flanges, 400# Flanges, Class 400 SS Flange

Available In Mumbai, India

Naysha Steel & Alloy is the leading provider of top-notch Stainless Steel 316 (ANSI Class 400) Flanges in Mumbai, India. We are proud to have a strong sense of dedication to our work and clients, therefore, Comprehensive range of Class 400 SS Flanges needed in industries for other applications is what we are offering. We are exact manufacturers of Stainless Steel 316 ANSI Class 400 Flanges with high resistance to corrosion, hence are preferable when used in challenging environments. These flanges are made from high-quality stainless steel, thus they can bear up extreme service conditions to maintain their long service life.

Our broad range of flanges includes the specially designed 400# Flanges which is compatible with and fits in many applications across all different kinds of industries. Whether you need flanges for pipe systems, chemical process, or marine applications, be sure that Naysha Steel and Alloy has you covered. Superior quality and ANSI standard -engineered Class 400 SS Flanges guarantee reliable performance and easy integration in your systems. Our flanges, which are comparable for size and appearance, offer easy installation and maintenance due to such features as perfect diameters and smoothing, therefore, saving your time and effort.

Customer satisfaction is our top priority at Naysha Steel and Alloy. Our knowledgeable staff who is committed to providing outstandingly excellent services and helping you select the right Stainless Steel 316 ANSI Class 400 Flanges that fully fits your specific requirements. Furthermore, we provide competitive pricing and also fast delivery which makes our buying process an easy stress-free one. While conversing about the high-grade stainless steel flanges, ensure Naysha Steel and Alloy to be a one-stop shopping for indisputable quality and dependability. Reach out to us now and find out more about our Class 400#Flanges. Let us help you get only the best products for your industry, with comfort and speed.

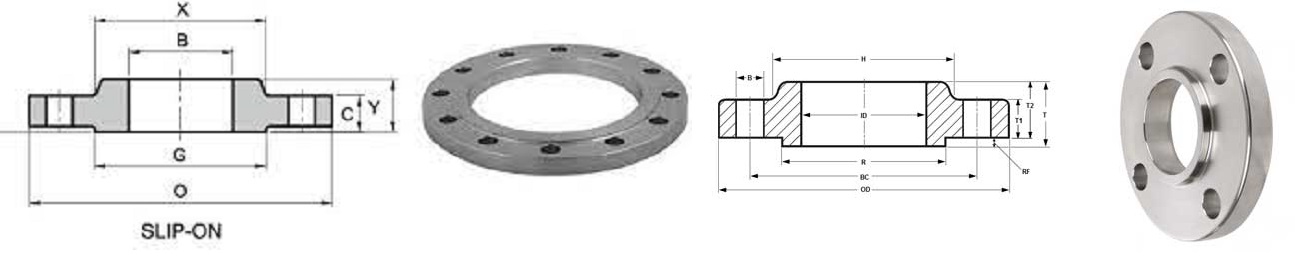

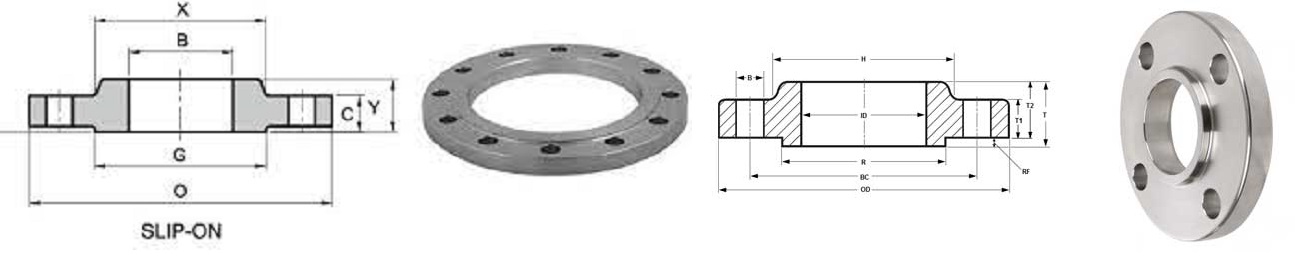

Understand Dimensions of Stainless Steel 316 400 Class Flange Dimensions To Simple diagram

Stainless Steel 316 400 Class flanges are indebted to piping systems, very known for their solid build and corrosion resistance. Naysha Steel and Alloy, the foremost stainless steel products company, manufacture such flanges, each of which is made in accordance with specific dimensions tailored to fit any systems or applications. The sizes of Stainless Steel 316 400 Class fittings follow their practical dimensions that were standardized for the sake of interchangeability and reliability across various systems. Consequently, these flanges are mostly designed according to the ANSI/ASME B16.5 standard that specifies the dimensions, tolerances, materials, and visual marks that are required for flanges.

In an overview diagram, diameters such as the OD (outer diameter), ID (inner diameter), bolt hole diameter, bolt circle diameter, and wall thickness can be recognized. “OD” here refers to the outer diameter of pipe while “ID” represents the inner diameter through which liquid flows. The bolt hole diameter and bolt circle diameter should enable a precise alignment and the use of bolts for fastening on the flange adjacent ones. Whilst on the other hand, the walls of the the pipes will remain thick enough to provide structural integrity and the ability to withstand the pressure and stress from the piping system.

Knowing these dimensions is very significant in the selection and installment of Stainless Steel 316 400 Class flanges, and this will result in better performance and sturdiness of the system. Naysha Steel and Alloy, recognized for their dedication to quality and the precise engineering for which their flanges are known, take comfort in the thought that their products meet or even exceed the industry quality standard, as well as the customers' diverse demands. Finally, a proper understanding of the Stainless Steel 316 400 Class flanges must be achieved to effectively refer to and apply within piping systems. Naysha Steel and Alloy’s expertise in all types of stainless steel material, such as flanges, provides our customers with ultimate product quality aligned with their specifications, giving a better performance and longer life.

Class 400 SS 3 04 Flange Chemical Composition Table

| Grade/ Marked Symbol |

Carbon (Max) |

Manganese (max) |

Silicon (maximum) |

Phosphorus (max) |

Sulfur (max) |

Chromium |

Molybdenum |

Nickel |

N |

| F304 |

0.08 |

2 |

0.75 |

0.045 |

0.030 |

18-20

|

- |

8-11

|

- |

| F304L |

0.035 |

2 |

1.00 |

0.045 |

0.030 |

18-20

|

- |

8-13

|

- |

| F316 |

0.08 |

2 |

0.75 |

0.045 |

0.030 |

16-18

|

2-3

|

10-14

|

64.845 |

| F316L |

0.035 |

2 |

1.00 |

0.045 |

0.030 |

16-18

|

2-3

|

10-14

|

68.89 |

SS 316 400 Class flanges Price List in Mumbai, India: Valid From 1st March 2024

Take a better look on price list of stainless steel and weld neck flanges in Mumbai, India

| SS 316 400 Class flanges Price |

| Size |

Aprox. Wt/Unit |

FOB INR |

CIF INR |

FOB USD |

CIF USD |

FOB STGP |

CIF STGP |

FOB EURO$ |

CIF EURO$ |

| 15mm |

0.54 |

543.95 |

591.25 |

8.242 |

8.958 |

5.551 |

6.033 |

9.890 |

10.750 |

| 20mm |

0.78 |

854.45 |

928.75 |

12.946 |

14.072 |

8.719 |

9.477 |

15.535 |

16.886 |

| 25mm |

1.12 |

1009.70 |

1097.50 |

15.298 |

16.629 |

10.303 |

11.199 |

18.358 |

19.955 |

| 32mm |

1.47 |

1179.90 |

1282.50 |

17.877 |

19.432 |

12.040 |

13.087 |

21.453 |

23.318 |

| 40mm |

1.90 |

1475.45 |

1603.75 |

22.355 |

24.299 |

15.056 |

16.365 |

26.826 |

29.159 |

| 50mm |

2.77 |

1707.75 |

1856.25 |

25.875 |

28.125 |

17.426 |

18.941 |

31.050 |

33.750 |

| 65mm |

4.49 |

2717.45 |

2953.75 |

41.173 |

44.754 |

27.729 |

30.140 |

49.408 |

53.705 |

| 80MM |

5.44 |

3105.00 |

3375.00 |

47.045 |

51.136 |

31.684 |

34.439 |

56.455 |

61.364 |

| 100mm |

7.69 |

4347.00 |

4725.00 |

65.864 |

71.591 |

44.357 |

48.214 |

79.036 |

85.909 |

| 125mm |

9.40 |

7452.00 |

8100.00 |

112.909 |

122.727 |

76.041 |

82.653 |

135.491 |

147.273 |

| 150mm |

11.82 |

9315.00 |

10125.00 |

141.136 |

153.409 |

95.051 |

103.316 |

169.364 |

184.091 |

| 200mm |

19.11 |

13972.50 |

15187.50 |

211.705 |

230.114 |

142.577 |

154.974 |

254.045 |

276.136 |

| 250mm |

26.19 |

18630.00 |

20250.00 |

282.273 |

306.818 |

190.102 |

206.633 |

338.727 |

368.182 |

Get an estimate within 10 minutes!

Stainless Steel Flanges, SS 316 400 Class Flanges Manufacturer, Class 400 SS 316 Flanges Manufacturer, 400# SS 316 Flanges Manufacturer, UNS S31803 Weld Neck Flanges Stockist, UNS S31803 Flanges Manufacturers,

UNS S31803 Flanges Exporter, UNS S32205 Flanges Stockist : Grades & Classes

(#)

- ASTM A182 F316/F316L: Standard austenitic stainless steel grade.

- ASTM A182 F347/F347H: Stabilized stainless steel grade with niobium addition.

- ASTM A182 F321/F321H: Stabilized stainless steel grade with titanium addition.

- ASTM A182 F316/F316L: Austenitic stainless steel with enhanced corrosion

resistance.

- ASTM A182 F53: Super duplex stainless steel grade with excellent corrosion resistance.

- Class 125: Class 125 Weld Neck Flange suitable for aggressive conditions.

- Class 150: Weld neck flange design for low-pressure applications.

- ASTM A182 F51: Duplex stainless steel grade with high strength and corrosion resistance.

- Class 600: Weld Neck Flange Class 600 designed for high-pressure applications.

- Class 300: Flanges suitable for moderate-pressure applications.

SS 316 Flange 400, 400# SS 316 Flanges, Stainless Steel 316 400 Class Flanges Specifications

| Specification Of : |

Weld Neck Stainless Steel Flanges |

| JIS Standards |

5K, 10K, 40K, 16K 20K 30K, 63K |

| Size Of Bore Diameter Flange |

NPS ≤ 10 |

| Manufacturer Of Standard Dimensions |

EN-1092 Flange, ASME B16.48 Flange, API605 Flange, BS4504 Flange, EN1092 Flange, UNI

Flange, ISO Flange, API7S-43 Flange, ANSI/ASME B16.5 Flange, API7S-15 Flange, MSS

S44 Flange, IS 2062 Flange, ASME B16.36 Flange, DIN Flange, AWWA C207 Flange, B16.47

Series A & B Flange, BS1560-3.1 Flange, ISO70051 Flange, API Flange, ASME Code for

12 inches Welding Neck Flanges.

|

| Minimum Pressure |

150# To 2500# |

| Flange Face Type |

Raised Face, Groove And Small Tongue Groove, RTJ, Weld Neck Flanges Flat Face, Large

Tongue & Large

Male-Female And Small Male-Female, Lap-Joint Face. |

| Top Six Type Of Flanges |

Threaded, Lap Joint, Socket-Weld, Blind, Slip-On or Weld Neck Flanges

|

| Standard Materials |

Duplex Steel & Super Duplex Steel, Copper Nickel, Wrought Iron, Inconel, Mild Steel,

Stainless Steel, Hastelloy, Cast Iron, Alloy Steel, Carbon Steel.

|

| Thickness Length |

NPS ≤ 18

|

| Welding neck flanges size |

(1/2") To (48")

|

| Manufacturing Process |

Forged/ Machined/ Heat Treated

|

| Other Type Of Flange |

Forged/ Plate/ Threaded

|

| Application |

Oil And Gas Industry

Power Plants Industry

Food Processing And Manufacturing

Waterworks Systems

Fossil Fuel Power Plants

Nuclear Power Application

Municipal Pipe Systems

|

Please find below our other manufacturing and Sales network in India : (Contact us

for detailed information for your nearest branches)

- Stainless Steel 316 400 Class flanges manufacturer and Manufacturer in Mumbai, India.

- Stainless Steel 316 400 Class flanges manufacturer and supplier in Nagpur, India.

- Stainless Steel 316 400 Class flanges manufacturer and stockists in Pune, India.

- Stainless Steel 316 400 Class flanges manufacturer and Exporter in Thane, India.

- Stainless Steel 316 400 Class flanges manufacturer and wholesalor in Nashik, India.

Frequently Asked Questions

What is a stainless steel weldneck flange?

A stainless steel weldneck flange is a type of pipe flange designed to be welded onto the

neck of a pipe. It provides a smooth, high-strength connection for joining pipes,

valves, and other equipment. All the standard Flange dimensional sizes are

Readily available at any Naysha Steel branch in India.

What types of stainless steel material grades are used for weldneck flanges?

Common stainless steel materials include 304, 316, and 321, among others. The choice of

stainless steel grade depends on the specific application and the required corrosion

resistance.

What sizes are available for stainless steel weldneck flanges?

Stainless steel weldneck flanges are available in a wide range of sizes, typically

ranging from 1/2 inch to several feet in diameter. The size you need depends on your

specific piping system requirements. All the standard Flange dimensional sizes are

Readily available at any Naysha Steel branch in India.

Can stainless steel weldneck flanges be used with other pipes?

Yes, stainless steel weldneck flanges can be used with pipes made of other materials,

provided the flange material is compatible with the pipe material, and the connection is

properly sealed.

Industries served by Stainless Steel SS 316 400 Class Flanges In Mumbai, India

In the oil and gas industry, blind Alloy Steel flanges are used in pipelines, storage tanks, and offshore platforms. They are employed for closing off openings during maintenance, repair, or when a branch connection is not required. Petrochemical plants utilize blind Alloy Steel flanges in equipment such as reactors, distillation columns, and storage vessels. These flanges provide a secure and leak-proof seal when closing off unused openings or isolating sections of the process.

Oil and Gas Industries

The oil and gas industry includes a wide range of from drilling and

production to refining and marketing. Some of the major players in this

include oil and gas companies, service providers, equipment.

Petroleum Industries

In the drilling process, stainless steel is used to make drill bits, pipes, and other

equipment that must withstand high pressures and temperatures. Stainless steel is

also used to make pumps, valves, and fittings for the transportation.

Shipbuilding in India

In storage applications, stainless steel is used to make tanks and containers that

can safely store corrosive and hazardous chemicals. It is also used in piping

systems for chemical transfer and distribution chemical industry.

Marking & Pricing

Products are packaged to ensure that there is no damage during of goods transport. In case of exports, standard export packaging is done with utmost care in wooden covering or boxing. All products are marked with Grade, Lot No, Size, Degree and our trade mark. On special requests we can also, make

customized marking on our products.

Quality Assurance

At Naysha Steel, all fittings and flanges are subject to strict inspection at each and every stage of the production process, from starting material

purchasing to product dispatch. They are visually examined for compliance to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards.

Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality compliance

of products.

Test Certificates: Manufacturer Test Certificate as per EN 10204 / 3.1B Raw Materials Certificate, 100% Radiography Test Report, Third

Party Inspection Report