Stainless Steel SS 316 (ASTM A182 F316) 300 Class Flanges Manufacturer And Supplier In Mumbai, India

Naysha Steel and Alloy, an industry-trusted manufacturer and supplier based in Mumbai, India, is a specialist in Stainless Steel SS 316 (ASTM A182 F316) 300 Class Flanges. Our flanges are diligently designed to meet the strictest quality requirements, guaranteeing reliability and efficiency for various industrial implementations. Created from premium quality stainless steel SS 316, our flanges have outstanding corrosion resistance and durability, which are ideal for such harsh environments as chemical processing, oil and gas, and petrochemical industries. Naysha Steel and Alloy caters for varied sizes and configurations to come up with tailored solutions that fit diverse projects. Our ability to provide excellence and customer satisfaction guarantees timely delivery and superior service. Selecting Naysha Steel and Alloy as your premium grade Stainless Steel SS 316 300 Class Flanges supplier will give your piping systems outstanding performance and durability.

SS 316 (ASTM A182 F316) 300 Class Flanges Manufacturer And Supplier In Mumbai, India

Naysha Steel & Alloy, a well-known manufacturer and supplier in Mumbai, India, delivers SS 316 (ASTM-A182-F316) 300 Class Flanges. Our flanges, made with high production standards, are to meet the ASTM requirements and hence give a perfect quality and functionality. Developed to be sturdy and long-lasting, these 300 Class knockouts are appropriate for plenty of industrial professions, such as chemical processing, oil and gas, and marine surroundings. Naysha Steel and Alloy, through its focus on customer satisfaction, continues to satisfy its customers with its exceptional products and services. Place your faith in us, since we supply Class Flanges from SS316 300 that guarantee maximum strength, corrosion resistance and durability for your piping systems.

Countless Benefits of SS 316 ASTM A182 F316 300 Class Flanges, ASTM A182 F316 300# SS 316 Flange:

The SS 316 ASTM A182 F316 300 Class Flanges are associated with so many advantages as same to the other types of flanges. Take a look for the key benefits of stainless steel weld neck flanges.

-

Easy Installation: SS 316 flanges from ASTM A182 F316, 300 grade offer a convenient solution for installation because of their standardized, easy to fit size allowing for reduced personnel needs. This will cut time and money for clients spending in installation phase.

-

Leak-Proof Design: Engineered ergonomically to create a tight seal, these flanges prevent leakage of fluids or gas, contributing to the pipe integrity, thus avoiding accidents.

-

Corrosion Resistance: Forged from premium stainless steel alloys, these flanges will not rust and corrosive environments like those found in the marine, chemical, and industrial workplaces.

-

High Strength: Designed specifically to handle pressures and temperatures conditions, and they are wear-resistant and they meet safety standards in a strict way.

-

Wide Range of Applications: They are able to meet diverse piping works’ needs by being versatile enough to be utilized in wide range of industries which come from oil and gas, chemicals, water treatment, and food processing sectors, and they are capable of connecting various pipe materials together.

SS 316 (ASTM A182 F316) 300 Class Flanges, (ASTM A182 F316) 300 Class Flanges, SS 316 300 Class Flanges, SS 316 300# Flanges, ASTM A182 F316 Stainless Steel 316 Flanges, Manufacturer And Supplier In Mumbai, India

Naysha Steel and Alloy, a Indian manufacturer and supplier situated in Mumbai, offers a wide range of Stainless steel 316 (ASTM A182 F316) 300 Class Flanges. Precisely manufactured out of high-grade stainless steel 316, our flanges afford great corrosion protection and endurance qualities suitable for use in many industrial settings. Meeting ASTM A182 F316 specifications, our 300 Class flanges are crafted with the ability to endure a high-pressure environment, making them functional for critical piping systems in industries like chemical processing, oil & gas, petrochemical, and marine.

SS 316 300# Flanges supplied by Naysha Steel and Alloy are manufactured with utmost care according to exacting requirements, so they would perform reliably and have the expected long-term integrity. With the concentration on quality and perfection, manufacturers make sure to comply with the stringent quality standards and the international norms, giving the customers an opportunity enjoy the peace of mind. As a reliable manufacturer and supplier, Naysha Steel and Alloy is proud of its ASTM A182 F316 Stainless Steel 316 Flanges that conform to the extensive needs of its customers. Our priority, customer satisfaction and timely delivery guarantees you will receive premium quality flanges that surpass your expectations with Naysha Steel and Alloy.

ASTM A182 F316 Stainless Steel 316 300 Class Flanges, SS 316 ASTM A182 F316 300 Class Flanges Size In Mumbai, India shop:

| Nominal Size |

Outside Diameter(OD) |

Min. Thickness(T) |

RF Dia.(R) |

No. of Bolt Holes |

Diameter of Holes |

Bolt Circle(BC) |

SO Bore ID(SB) |

WN Bore ID(WB) |

Dia. Hub Base(HB) |

Dia. of Hub Top(HT) |

SO LTH(SL) |

WN LTH(WL) |

| 1⁄2 |

3.50 |

0.38 |

1.38 |

4 |

0.62 |

2.38 |

0.88 |

0.62 |

1.19 |

0.84 |

0.56 |

1.81 |

| 3⁄4 |

3.88 |

0.44 |

1.69 |

4 |

0.62 |

2.75 |

1.09 |

0.82 |

1.50 |

1.05 |

0.56 |

2.00 |

| 1 |

4.25 |

0.50 |

2.00 |

4 |

0.62 |

3.12 |

1.36 |

1.05 |

1.94 |

1.32 |

0.62 |

2.12 |

| 11⁄4 |

4.62 |

0.56 |

2.50 |

4 |

0.62 |

3.50 |

1.70 |

1.38 |

2.31 |

1.66 |

0.75 |

2.19 |

| 11⁄2 |

5.00 |

0.62 |

2.88 |

4 |

0.62 |

3.88 |

1.95 |

1.61 |

2.56 |

1.90 |

0.81 |

2.38 |

| 2 |

6.00 |

0.69 |

3.62 |

4 |

0.75 |

4.75 |

2.44 |

2.07 |

3.06 |

2.38 |

0.94 |

2.44 |

| 21⁄2 |

7.00 |

0.81 |

4.12 |

4 |

0.75 |

5.50 |

2.94 |

2.47 |

3.56 |

2.88 |

1.06 |

2.69 |

| 3 |

7.50 |

0.88 |

5.00 |

4 |

0.75 |

6.00 |

3.57 |

3.07 |

4.25 |

3.50 |

1.12 |

2.69 |

| 31⁄2 |

8.50 |

0.88 |

5.50 |

8 |

0.75 |

7.00 |

4.07 |

3.55 |

4.81 |

4.00 |

1.19 |

2.75 |

| 4 |

9.00 |

0.88 |

6.19 |

8 |

0.75 |

7.50 |

4.57 |

4.03 |

5.31 |

4.50 |

1.25 |

2.94 |

| 5 |

10.00 |

0.88 |

7.31 |

8 |

0.88 |

8.50 |

5.66 |

5.05 |

6.44 |

5.56 |

1.38 |

3.44 |

| 6 |

11.00 |

0.94 |

8.50 |

8 |

0.88 |

9.50 |

6.72 |

6.07 |

7.56 |

6.63 |

1.50 |

3.44 |

| 8 |

13.50 |

1.06 |

10.62 |

8 |

0.88 |

11.75 |

8.72 |

7.98 |

9.69 |

8.63 |

1.69 |

3.94 |

| 10 |

16.00 |

1.12 |

12.75 |

12 |

1.00 |

14.25 |

10.88 |

10.02 |

12.00 |

10.75 |

1.88 |

3.94 |

| 12 |

19.00 |

1.19 |

15.00 |

12 |

1.00 |

17.00 |

12.88 |

12.00 |

14.38 |

12.75 |

2.12 |

4.44 |

| 14 |

21.00 |

1.31 |

16.25 |

12 |

1.12 |

18.75 |

14.14 |

13.25 |

15.75 |

14.00 |

2.19 |

4.94 |

| 16 |

23.50 |

1.38 |

18.50 |

16 |

1.12 |

21.25 |

16.16 |

15.25 |

18.00 |

16.00 |

2.44 |

4.94 |

| 18 |

25.00 |

1.50 |

21.00 |

16 |

1.25 |

22.75 |

18.18 |

17.25 |

19.88 |

18.00 |

2.62 |

5.44 |

| 20 |

27.50 |

1.62 |

23.00 |

20 |

1.25 |

25.00 |

20.20 |

19.25 |

22.00 |

20.00 |

2.81 |

5.62 |

| 22 |

29.50 |

1.75 |

25.25 |

20 |

1.38 |

27.25 |

22.22 |

21.25 |

24.25 |

22.00 |

3.07 |

5.82 |

| 24 |

32.00 |

1.81 |

27.25 |

20 |

1.38 |

29.50 |

24.25 |

23.25 |

26.12 |

24.00 |

3.19 |

5.94 |

(ASTM A182 F316), Stainless Steel 316, ANSI Class 300 Flanges, ASTM A182 F316 300# Flanges, Class 300 SS Flange

Available In Mumbai, India

Naysha Steel and Alloy, the long known supplier of Mumbai, India, gives premium ASTM A182 F316 Stainless Steel 316 ANSI Class 300 Flanges and diverse industries demand. The Grade 300# flanges are made in compliance with ASTM A182 F316 standards, and are built to perform reliably under strict conditions. The largely made from 316 stainless steel Class 300 SS flanges possess top flight corrosion resistance due to which they are suitable for environments such as chemical processing, oil and gas and marine. These flanges work up to 740 psi (approximately 51 bar) pressures at ambient temperatures. This is ANSI class 300 designation.

Our complete ASTM A182 F316 300# flange inventory includes the slip-on, weld neck, threaded, blind, and socket weld flanges which enables our customers to use varied piping joint designs for their specific requirements. As a result of high precision and detail of workmanship, our flanges are leak-free and more than easy to install. We assure superior quality and customer reliability by providing F316 300 ASTM A182 grade flanges that conform to international specifications and stern testing. We are fully committed to the ideal of top-notch delivery while at the same time ensuring pricing competition and a quality buying experience for our clients.

Select Naysha Steel and Alloy for a reliable clade 300 SS flanges that are exceptionally tough-built to participate in piping systems with long lifespan. You are invited to rely on our expertise and many years' experience to execute your stainless steel flange order in the best possible way. We offer a comprehensive range of ASTM A182 F316 stainless steel 300# Flanges with attention to quality to help you revamp your piping systems. Reach us today for better solutions.

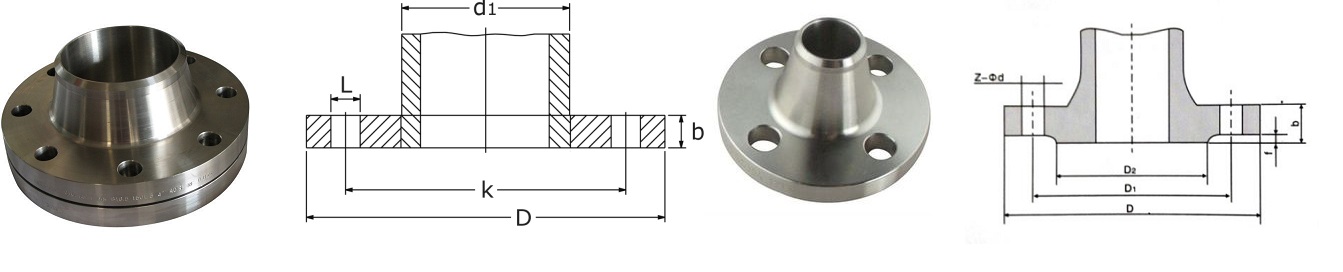

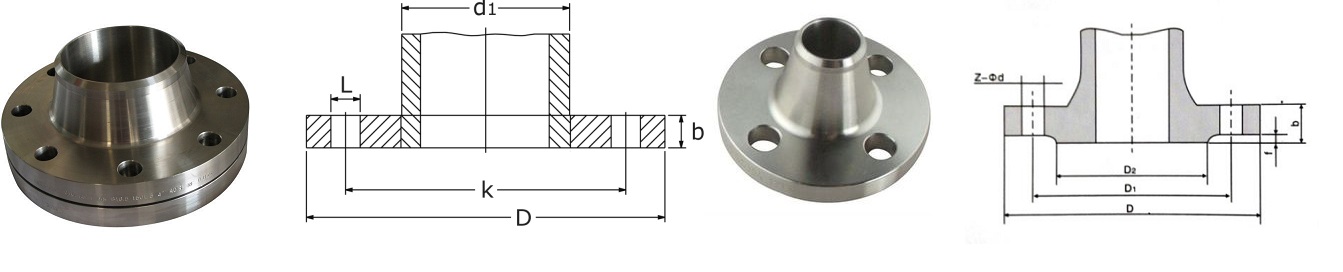

Understand Dimensions of ASTM A182 F316 Stainless Steel 316 300 Class Flange Dimensions To Simple diagram

Naysha Steel and alloy is the manufacturer of ASTM A182 F316 stainless steel 316 300 class flanges which artwork dimensions that fit the challenging standards of various industries. The precise dimensions of these flanges are of critical importance for correctly fitting pipes together and the pipe-line performance. ANSI A182 F316 Stainless Steel 316 300 Class Flanges are usually following the standard dimensional values given by two ANSI specifications; ASME B16.5 and ASME B16.47 (B16.47 is ASME’s specification for stainless steel flanges). This designed flange lines are available from ½-inch, 48-inch, and their specific pressure ratings are 150, 300, 600, 900, 1500, and 2500.

Visual representation of two-dimensional description of these flanges can be an easy way to show the dimensions of the outer diameter, the diameter of bolt holes and the size of the bolts themselves, hub diameter, as well as the overall thickness of the flanges. Besides keeping this in mind, one should also account for the facing type, which can be either raised face (RF), flat face (FF) or ring joint (RTJ), and is generally marked with a letter for the specific application type as well as any sealing requirements.

With her correct dimensions and specifications, Nyshe Steel and Alloy empowers customers that they can safely involve these ASTM A182 F316 Stainless Steel 316 300 Class Flanges while they are involved in their projects. Being responsible for our work, we guarantee that our flanges comply with industrial standards, and always strive for better results, thus proving our capacity to keep up with the specific demands of the industry. Chose Naysha Steel and Alloy and be fully confident in top-quality stainless steel flanges that combine unparalleled affordability with ultimate credibility.

ASMT A182 Class 300 SS 316 Flange Chemical Composition Table

| Grade/ Marked Symbol |

Carbon (Max) |

Manganese (max) |

Silicon (maximum) |

Phosphorus (max) |

Sulfur (max) |

Chromium |

Molybdenum |

Nickel |

N |

| F304 |

0.08 |

2 |

0.75 |

0.045 |

0.030 |

18-20

|

- |

8-11

|

- |

| F304L |

0.035 |

2 |

1.00 |

0.045 |

0.030 |

18-20

|

- |

8-13

|

- |

| F316 |

0.08 |

2 |

0.75 |

0.045 |

0.030 |

16-18

|

2-3

|

10-14

|

64.845 |

| F316L |

0.035 |

2 |

1.00 |

0.045 |

0.030 |

16-18

|

2-3

|

10-14

|

68.89 |

SS 316 ASMT A182 F316 300 Class flanges Price List in Mumbai, India: Valid From 1st March 2024

Take a better look on price list of stainless steel and weld neck flanges in Mumbai, India

| SS 316 ASMT A182 F316 300 Class flanges Price |

| Size |

Aprox. Wt/Unit |

FOB INR |

CIF INR |

FOB USD |

CIF USD |

FOB STGP |

CIF STGP |

FOB EURO$ |

CIF EURO$ |

| 15mm |

0.54 |

543.95 |

591.25 |

8.242 |

8.958 |

5.551 |

6.033 |

9.890 |

10.750 |

| 20mm |

0.78 |

854.45 |

928.75 |

12.946 |

14.072 |

8.719 |

9.477 |

15.535 |

16.886 |

| 25mm |

1.12 |

1009.70 |

1097.50 |

15.298 |

16.629 |

10.303 |

11.199 |

18.358 |

19.955 |

| 32mm |

1.47 |

1179.90 |

1282.50 |

17.877 |

19.432 |

12.040 |

13.087 |

21.453 |

23.318 |

| 40mm |

1.90 |

1475.45 |

1603.75 |

22.355 |

24.299 |

15.056 |

16.365 |

26.826 |

29.159 |

| 50mm |

2.77 |

1707.75 |

1856.25 |

25.875 |

28.125 |

17.426 |

18.941 |

31.050 |

33.750 |

| 65mm |

4.49 |

2717.45 |

2953.75 |

41.173 |

44.754 |

27.729 |

30.140 |

49.408 |

53.705 |

| 80MM |

5.44 |

3105.00 |

3375.00 |

47.045 |

51.136 |

31.684 |

34.439 |

56.455 |

61.364 |

| 100mm |

7.69 |

4347.00 |

4725.00 |

65.864 |

71.591 |

44.357 |

48.214 |

79.036 |

85.909 |

| 125mm |

9.40 |

7452.00 |

8100.00 |

112.909 |

122.727 |

76.041 |

82.653 |

135.491 |

147.273 |

| 150mm |

11.82 |

9315.00 |

10125.00 |

141.136 |

153.409 |

95.051 |

103.316 |

169.364 |

184.091 |

| 200mm |

19.11 |

13972.50 |

15187.50 |

211.705 |

230.114 |

142.577 |

154.974 |

254.045 |

276.136 |

| 250mm |

26.19 |

18630.00 |

20250.00 |

282.273 |

306.818 |

190.102 |

206.633 |

338.727 |

368.182 |

Get an estimate within 10 minutes!

Stainless Steel Flanges ANSI 300, IS6392 Flanges, SS 316 300 Class Flanges

Manufacturer, Class 300 SS 316 Flanges Manufacturer, ASMT A182 F316 300# SS 316 Flanges Manufacturer, UNS S31803 Weld Neck Flanges Stockist, UNS S31803 Flanges Manufacturers,

UNS S31803 Flanges Exporter, UNS S32205 Flanges Stockist : Grades & Classes

(#)

- ASTM A182 F304/F304L: Standard austenitic stainless steel grade.

- ASTM A182 F347/F347H: Stabilized stainless steel grade with niobium addition.

- ASTM A182 F321/F321H: Stabilized stainless steel grade with titanium addition.

- ASTM A182 F316/F316L: Austenitic stainless steel with enhanced corrosion

resistance.

- ASTM A182 F53: Super duplex stainless steel grade with excellent corrosion resistance.

- Class 125: Class 125 Weld Neck Flange suitable for aggressive conditions.

- Class 300: Weld neck flange design for low-pressure applications.

- ASTM A182 F51: Duplex stainless steel grade with high strength and corrosion resistance.

- Class 600: Weld Neck Flange Class 600 designed for high-pressure applications.

- Class 300: Flanges suitable for moderate-pressure applications.

SS 316 Flange 300, 300# ASMT A182 F316 SS 316 Flanges, Stainless Steel 316 ASMT A182 F316 300 Class Flanges Specifications

| Specification Of : |

Weld Neck Stainless Steel Flanges |

| JIS Standards |

5K, 10K, 40K, 16K 20K 30K, 63K |

| Size Of Bore Diameter Flange |

NPS ≤ 10 |

| Manufacturer Of Standard Dimensions |

EN-1092 Flange, ASME B16.48 Flange, API605 Flange, BS4504 Flange, EN1092 Flange, UNI

Flange, ISO Flange, API7S-43 Flange, ANSI/ASME B16.5 Flange, API7S-15 Flange, MSS

S44 Flange, IS 2062 Flange, ASME B16.36 Flange, DIN Flange, AWWA C207 Flange, B16.47

Series A & B Flange, BS1560-3.1 Flange, ISO70051 Flange, API Flange, ASME Code for

12 inches Welding Neck Flanges.

|

| Minimum Pressure |

150# To 2500# |

| Flange Face Type |

Raised Face, Groove And Small Tongue Groove, RTJ, Weld Neck Flanges Flat Face, Large

Tongue & Large

Male-Female And Small Male-Female, Lap-Joint Face. |

| Top Six Type Of Flanges |

Threaded, Lap Joint, Socket-Weld, Blind, Slip-On or Weld Neck Flanges

|

| Standard Materials |

Duplex Steel & Super Duplex Steel, Copper Nickel, Wrought Iron, Inconel, Mild Steel,

Stainless Steel, Hastelloy, Cast Iron, Alloy Steel, Carbon Steel.

|

| Thickness Length |

NPS ≤ 18

|

| Welding neck flanges size |

(1/2") To (48")

|

| Manufacturing Process |

Forged/ Machined/ Heat Treated

|

| Other Type Of Flange |

Forged/ Plate/ Threaded

|

| Application |

Oil And Gas Industry

Power Plants Industry

Food Processing And Manufacturing

Waterworks Systems

Fossil Fuel Power Plants

Nuclear Power Application

Municipal Pipe Systems

|

Please find below our other manufacturing and Sales network in India : (Contact us

for detailed information for your nearest branches)

- Stainless Steel 316 ASMT A182 F316 300 Class flanges manufacturer and Manufacturer in Mumbai, India.

- Stainless Steel 316 ASMT A182 F316 300 Class flanges manufacturer and supplier in Nagpur, India.

- Stainless Steel 316 ASMT A182 F316 300 Class flanges manufacturer and stockists in Pune, India.

- Stainless Steel 316 ASMT A182 F316 300 Class flanges manufacturer and Exporter in Thane, India.

- Stainless Steel 316 ASMT A182 F316 300 Class flanges manufacturer and wholesalor in Nashik, India.

Frequently Asked Questions

What is a stainless steel weldneck flange?

A stainless steel weldneck flange is a type of pipe flange designed to be welded onto the

neck of a pipe. It provides a smooth, high-strength connection for joining pipes,

valves, and other equipment. All the standard Flange dimensional sizes are

Readily available at any Naysha Steel branch in India.

What types of stainless steel material grades are used for weldneck flanges?

Common stainless steel materials include 304, 316, and 321, among others. The choice of

stainless steel grade depends on the specific application and the required corrosion

resistance.

What sizes are available for stainless steel weldneck flanges?

Stainless steel weldneck flanges are available in a wide range of sizes, typically

ranging from 1/2 inch to several feet in diameter. The size you need depends on your

specific piping system requirements. All the standard Flange dimensional sizes are

Readily available at any Naysha Steel branch in India.

Can stainless steel weldneck flanges be used with other pipes?

Yes, stainless steel weldneck flanges can be used with pipes made of other materials,

provided the flange material is compatible with the pipe material, and the connection is

properly sealed.

Industries served by Stainless Steel SS 316 (ASTM A182 F316) 300 Class Flanges In Mumbai, India

In the oil and gas industry, blind Alloy Steel flanges are used in pipelines, storage tanks, and offshore platforms. They are employed for closing off openings during maintenance, repair, or when a branch connection is not required. Petrochemical plants utilize blind Alloy Steel flanges in equipment such as reactors, distillation columns, and storage vessels. These flanges provide a secure and leak-proof seal when closing off unused openings or isolating sections of the process.

Oil and Gas Industries

The oil and gas industry includes a wide range of from drilling and

production to refining and marketing. Some of the major players in this

include oil and gas companies, service providers, equipment.

Petroleum Industries

In the drilling process, stainless steel is used to make drill bits, pipes, and other

equipment that must withstand high pressures and temperatures. Stainless steel is

also used to make pumps, valves, and fittings for the transportation.

Shipbuilding in India

In storage applications, stainless steel is used to make tanks and containers that

can safely store corrosive and hazardous chemicals. It is also used in piping

systems for chemical transfer and distribution chemical industry.

Marking & Pricing

Products are packaged to ensure that there is no damage during of goods transport. In case of exports, standard export packaging is done with utmost care in wooden covering or boxing. All products are marked with Grade, Lot No, Size, Degree and our trade mark. On special requests we can also, make

customized marking on our products.

Quality Assurance

At Naysha Steel, all fittings and flanges are subject to strict inspection at each and every stage of the production process, from starting material

purchasing to product dispatch. They are visually examined for compliance to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards.

Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality compliance

of products.

Test Certificates: Manufacturer Test Certificate as per EN 10204 / 3.1B Raw Materials Certificate, 100% Radiography Test Report, Third

Party Inspection Report