Stainless Steel SS 304 2500 Class Flanges Manufacturer And Supplier In Mumbai, India

Naysha Steel and Alloy supplies industry-leading Stainless Steel 304 2500 Class Flanges which are engineered to meet the exacting specifications of diverse industrial uses thus guaranteeing accuracy and reliability. We are based in Mumbai, India and are recognized as reliable manufacturers and suppliers, dedicated to meeting the highest standards in each of our products. Our SS 304 2500 Class FLANGES represent the most corrosion resistant and durable class of materials on the market and work perfectly in critical applications in many branches of industry including oil and gas, chemical, and petrochemical. With a commitment to deliver topnotch quality products and high level of customer satisfaction,we make sure every flange is checked for valuable standards. Naysha Steel and Alloys, the makers of best-grade stainless steel flanges, are the quality supplier of the products that will guarantee exceptional performance and long timespan, and unite them with new benchmarks in reliability and efficiency. Trust us with the flanges and be confident to enjoy personalised craftsmanship and professional service.

SS 304 2500 Class Flanges Manufacturer And Supplier In Mumbai, India

Naysha Steel and Alloy invites customers to check our line of Stainless Steel 304 Class 2500, in which all the parts are thoughtfully designed and fashioned to meet the industry’s most stringent specifications. Our flanges have superior durable and corrosion resistance characteristics that are suitable for winning application in several industries. Through accurate engineering and the use of only the highest grade materials, our flanges will showcase the highest level of reliability and endurance. We at our company just can’t make a compromise when it comes to quality. Therefore, we promise exquisite products trusted by our customers. For the best grade of stainless steel 304 2500 class flange available, go to Naysha Steel & Alloy to provided reliability and give more for the price. Should you be in a need for a flange, let us help you pick us and experience excellence in every product.

Countless Benefits of SS 304 2500 Class Flanges, 2500# SS 304 Flange:

The SS 304 2500 Class Flanges are associated with so many advantages as same to the other types of flanges. Take a look for the key benefits of stainless steel weld neck flanges.

- Easy Installation: SS 304 2500 Class Flanges are very convenient types of flange with their simple installation, standard interface, cheap fabrication, and push-on bolt connection. This means that it is easy to install and lowers the cost of installation.

- Leak-Proof Design: Very close tolerance and the precision fit required in pipe or joint SS 304 2500 Class ensure the perfect tight seals and prevent leaks, thus there will be on repeated inspection to either rectify or replacement of any part which means there will be no second visits no cost and downtime.

- Corrosion Resistance: The SS 304 2500 grade flanges, which are main channel of transportation for the highly pressurized conductors, are manufactured by using high chromium-nickel stainless steel that has the extraordinary property of resistance to each lithium crime. Thus, the longevity as well as the stability of the system is increased without the damage of the system in the harsh environments.

- High Strength: This class of flanges reinforces structures due to its resistance to corrosion and high impact resistance properties, making them suitable for very harsh use condition. these assemblages which are referred to as workhorses on critical operations means high reliability in use.

- Wide Range of Applications: Being flexible and reliable, the Flanges made of the SS 304 2500 Class stone is of prime importance for multiple places in offices, including mainly petrochemical plants and food processing agencies, due to this characteristic.

SS 304 2500 Class Flanges, 2500 Class Flanges, SS 304 2500# Flanges, Stainless Steel 304 Flanges, Manufacturer And Supplier In Mumbai, India

Naysha Steel and Alloy are the Stainless Steel 304 2500 Class Flanges manufacturers and supplies, with offices in Mumbai, India. Our 2500 SS 304 Class Flanges are welded with a special attention to detail using this high quality material, permitting us to split a good performance even under very stressful industrial conditions. The goal is beyond making products accurately according to the required specifications as well as following the relevant standards. For this reason, it is ensured that our components show reliable performance and are durable. Actually, we are aware that at Naysha Steel and Alloy, the flanges are one of the most vital elements in all sectors of industries where they are being used separately or combined i.e. from the petrochemical plants to food processing units. Having an experienced and knowledgeable staff and using modern production techniques and severe quality control procedures is the key to the success of our company in making perfect flanges and supplying them on the customer’s demand.

Regardless whether you are requesting standard size or specifications,our carefully built Stainless Steel 304 Flanges inventory covers the whole scope of various more requirements. Drawing from an abundance of knowledge and technical skills, we are devoted to giving the maximum quality of service and products that even surpass all the high expectations. Pick Naysha Steel and Alloy as your leading supplier of top-of-the-line SS 304 2500 Class Flanges known to guarantee ease of attachment with your applications and operational efficiency in and around your systems. Be ready for the innovative experience of reliability and perfection as we are leaders of the specialized flange solutions.

Stainless Steel 304 2500 Class Flanges, SS 304 2500 Class Flanges Size In Mumbai, India shop:

| Nominal Size |

Outside Diameter(OD) |

Min. Thickness(T) |

RF Dia.(R) |

No. of Bolt Holes |

Diameter of Holes |

Bolt Circle(BC) |

SO Bore ID(SB) |

WN Bore ID(WB) |

Dia. Hub Base(HB) |

Dia. of Hub Top(HT) |

SO LTH(SL) |

WN LTH(WL) |

| 1⁄2 |

3.50 |

0.38 |

1.38 |

4 |

0.62 |

2.38 |

0.88 |

0.62 |

1.19 |

0.84 |

0.56 |

1.81 |

| 3⁄4 |

3.88 |

0.44 |

1.69 |

4 |

0.62 |

2.75 |

1.09 |

0.82 |

1.50 |

1.05 |

0.56 |

2.00 |

| 1 |

4.25 |

0.50 |

2.00 |

4 |

0.62 |

3.12 |

1.36 |

1.05 |

1.94 |

1.32 |

0.62 |

2.12 |

| 11⁄4 |

4.62 |

0.56 |

2.50 |

4 |

0.62 |

3.50 |

1.70 |

1.38 |

2.31 |

1.66 |

0.75 |

2.19 |

| 11⁄2 |

5.00 |

0.62 |

2.88 |

4 |

0.62 |

3.88 |

1.95 |

1.61 |

2.56 |

1.90 |

0.81 |

2.38 |

| 2 |

6.00 |

0.69 |

3.62 |

4 |

0.75 |

4.75 |

2.44 |

2.07 |

3.06 |

2.38 |

0.94 |

2.44 |

| 21⁄2 |

7.00 |

0.81 |

4.12 |

4 |

0.75 |

5.50 |

2.94 |

2.47 |

3.56 |

2.88 |

1.06 |

2.69 |

| 3 |

7.50 |

0.88 |

5.00 |

4 |

0.75 |

6.00 |

3.57 |

3.07 |

4.25 |

3.50 |

1.12 |

2.69 |

| 31⁄2 |

8.50 |

0.88 |

5.50 |

8 |

0.75 |

7.00 |

4.07 |

3.55 |

4.81 |

4.00 |

1.19 |

2.75 |

| 4 |

9.00 |

0.88 |

6.19 |

8 |

0.75 |

7.50 |

4.57 |

4.03 |

5.31 |

4.50 |

1.25 |

2.94 |

| 5 |

10.00 |

0.88 |

7.31 |

8 |

0.88 |

8.50 |

5.66 |

5.05 |

6.44 |

5.56 |

1.38 |

3.44 |

| 6 |

11.00 |

0.94 |

8.50 |

8 |

0.88 |

9.50 |

6.72 |

6.07 |

7.56 |

6.63 |

1.50 |

3.44 |

| 8 |

13.50 |

1.06 |

10.62 |

8 |

0.88 |

11.75 |

8.72 |

7.98 |

9.69 |

8.63 |

1.69 |

3.94 |

| 10 |

16.00 |

1.12 |

12.75 |

12 |

1.00 |

14.25 |

10.88 |

10.02 |

12.00 |

10.75 |

1.88 |

3.94 |

| 12 |

19.00 |

1.19 |

15.00 |

12 |

1.00 |

17.00 |

12.88 |

12.00 |

14.38 |

12.75 |

2.12 |

4.44 |

| 14 |

21.00 |

1.31 |

16.25 |

12 |

1.12 |

18.75 |

14.14 |

13.25 |

15.75 |

14.00 |

2.19 |

4.94 |

| 16 |

23.50 |

1.38 |

18.50 |

16 |

1.12 |

21.25 |

16.16 |

15.25 |

18.00 |

16.00 |

2.44 |

4.94 |

| 18 |

25.00 |

1.50 |

21.00 |

16 |

1.25 |

22.75 |

18.18 |

17.25 |

19.88 |

18.00 |

2.62 |

5.44 |

| 20 |

27.50 |

1.62 |

23.00 |

20 |

1.25 |

25.00 |

20.20 |

19.25 |

22.00 |

20.00 |

2.81 |

5.62 |

| 22 |

29.50 |

1.75 |

25.25 |

20 |

1.38 |

27.25 |

22.22 |

21.25 |

24.25 |

22.00 |

3.07 |

5.82 |

| 24 |

32.00 |

1.81 |

27.25 |

20 |

1.38 |

29.50 |

24.25 |

23.25 |

26.12 |

24.00 |

3.19 |

5.94 |

Stainless Steel 304, ANSI Class 2500 Flanges, 2500# Flanges, Class 2500 SS Flange

Available In Mumbai, India

Naysha Steel and Alloy releases Stainless Steel 304 Class 2500 Flanges with exclusive ANSI Class 2500 Flanges that are made of the finest class 2500 flanges to meet high-pressure requirements. With accuracy and professionalism, the 2500# flanges are made with the highest grade of our stainless steel materials. These materials are known for the highest level of endurance, resistance against corrosion, and durability for the harshest environment.

In Mumbai, India, “Naysha Steel and Alloy”, we are the leading supplier of 2500SS flanges that meet the stringent industry standards and go beyond your expectations. We have a vast variety of components, thus making it possible for the parts to be released on time so as to guarantee the projects are completed on time properly and efficiently. Quality production excellence is our top propriety. Therefore, all the production processes are closely monitored on all stages using advanced techniques with a high quality assurance and strict quality control measures.

These stainless steel 304 2500 class flanges are the perfect fit for petrochemical, oil and gas, chemical processing, or any other industrial application where the highest pressure demand is concerned to prevent operational safety risks while also ensuring operational efficiency. In addition to our highly performing team of experts and world-class customer support services, Naysha Steel and Alloy is geared ready to meet your flanges demand with a specialization degree that is unprecedented both in the service as well as the reliability. Discover the remarkable difference of top-rate quality and customer service with Naysha Steel and Alloy.

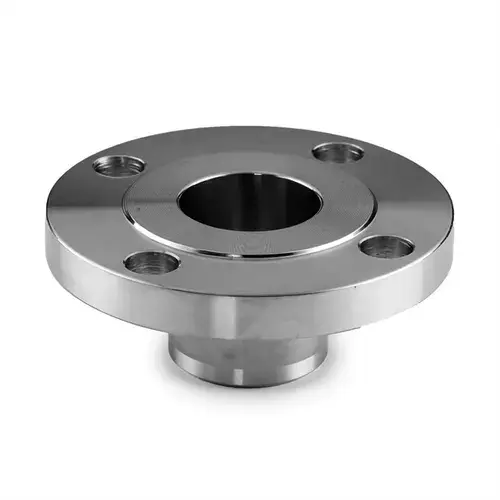

Understand Dimensions of Stainless Steel 304 2500 Class Flange Dimensions To Simple diagram

At Naysha Steel and Alloy, we make it a priority to be able to give a wide understand of technical features of our products. Our industry grade Stainless Steel class 304 2500 flanges are made and trained to conform to industry standard and the customer expectations. The critical aspect of these flanges is the dimension, which is necessary for conflict-free connection of the tube bundle with other pipe systems.

The SS304 2500 Class Flanges are known for their strong structure and that can withstand corrosive environment. That is why they are very suitable for application where tough environment is an issue. These flanges with the pressure rating 2500 Class have been engineered to withstand high pressures and hence they are trusted for effective performance under extreme conditions. To better explain our Steels 304 2500 Class Flanges, we produce a diagram of their dimensions. The diagram with measurements like outer diameter, bolt width, hole spacing size, and flange thickness are displayed in this sketch for quick and easy installation as well as identification of these bolts.

Our Stainless Steel 304 2500 Class Flanges, whether you are in oil and gas, petrochemical or industrial sectors, stand out due to their impeccable durability and flexibility. We have used one of the best materials in the market, Naysha Steel to make sure that the product that you get is as good as it can get with an assurance of durability as offered by Alloy. Trust Naysha Steel and Alloy for 100% grade products that greatly meet the high quality standards thereby making your production rise to a new peak. If you want to experience the superiority of quality, check out our full list of Stainless Steel 304 2500 Class Flanges now.

Class 2500 SS 304 Flange Chemical Composition Table

| Grade/ Marked Symbol |

Carbon (Max) |

Manganese (max) |

Silicon (maximum) |

Phosphorus (max) |

Sulfur (max) |

Chromium |

Molybdenum |

Nickel |

N |

| F304 |

0.08 |

2 |

0.75 |

0.045 |

0.030 |

18-20

|

- |

8-11

|

- |

| F304L |

0.035 |

2 |

1.00 |

0.045 |

0.030 |

18-20

|

- |

8-13

|

- |

| F316 |

0.08 |

2 |

0.75 |

0.045 |

0.030 |

16-18

|

2-3

|

10-14

|

64.845 |

| F316L |

0.035 |

2 |

1.00 |

0.045 |

0.030 |

16-18

|

2-3

|

10-14

|

68.89 |

SS 304 2500 Class flanges Price List in Mumbai, India: Valid From 1st March 2024

Take a better look on price list of stainless steel and weld neck flanges in Mumbai, India

| SS 304 2500 Class flanges Price |

| Size |

Aprox. Wt/Unit |

FOB INR |

CIF INR |

FOB USD |

CIF USD |

FOB STGP |

CIF STGP |

FOB EURO$ |

CIF EURO$ |

| 15mm |

0.54 |

543.95 |

591.25 |

8.242 |

8.958 |

5.551 |

6.033 |

9.890 |

10.750 |

| 20mm |

0.78 |

854.45 |

928.75 |

12.946 |

14.072 |

8.719 |

9.477 |

15.535 |

16.886 |

| 25mm |

1.12 |

1009.70 |

1097.50 |

15.298 |

16.629 |

10.303 |

11.199 |

18.358 |

19.955 |

| 32mm |

1.47 |

1179.90 |

1282.50 |

17.877 |

19.432 |

12.040 |

13.087 |

21.453 |

23.318 |

| 40mm |

1.90 |

1475.45 |

1603.75 |

22.355 |

24.299 |

15.056 |

16.365 |

26.826 |

29.159 |

| 50mm |

2.77 |

1707.75 |

1856.25 |

25.875 |

28.125 |

17.426 |

18.941 |

31.050 |

33.750 |

| 65mm |

4.49 |

2717.45 |

2953.75 |

41.173 |

44.754 |

27.729 |

30.140 |

49.408 |

53.705 |

| 80MM |

5.44 |

3105.00 |

3375.00 |

47.045 |

51.136 |

31.684 |

34.439 |

56.455 |

61.364 |

| 100mm |

7.69 |

4347.00 |

4725.00 |

65.864 |

71.591 |

44.357 |

48.214 |

79.036 |

85.909 |

| 125mm |

9.40 |

7452.00 |

8100.00 |

112.909 |

122.727 |

76.041 |

82.653 |

135.491 |

147.273 |

| 150mm |

11.82 |

9315.00 |

10125.00 |

141.136 |

153.409 |

95.051 |

103.316 |

169.364 |

184.091 |

| 200mm |

19.11 |

13972.50 |

15187.50 |

211.705 |

230.114 |

142.577 |

154.974 |

254.045 |

276.136 |

| 250mm |

26.19 |

18630.00 |

20250.00 |

282.273 |

306.818 |

190.102 |

206.633 |

338.727 |

368.182 |

Get an estimate within 10 minutes!

Stainless Steel Flanges, SS 304 2500 Class Flanges Manufacturer, Class 2500 SS 304 Flanges Manufacturer, 2500# SS 304 Flanges Manufacturer, UNS S31803 Weld Neck Flanges Stockist, UNS S31803 Flanges Manufacturers,

UNS S31803 Flanges Exporter, UNS S32205 Flanges Stockist : Grades & Classes

(#)

- ASTM A182 F304/F304L: Standard austenitic stainless steel grade.

- ASTM A182 F347/F347H: Stabilized stainless steel grade with niobium addition.

- ASTM A182 F321/F321H: Stabilized stainless steel grade with titanium addition.

- ASTM A182 F316/F316L: Austenitic stainless steel with enhanced corrosion

resistance.

- ASTM A182 F53: Super duplex stainless steel grade with excellent corrosion resistance.

- Class 125: Class 125 Weld Neck Flange suitable for aggressive conditions.

- Class 150: Weld neck flange design for low-pressure applications.

- ASTM A182 F51: Duplex stainless steel grade with high strength and corrosion resistance.

- Class 600: Weld Neck Flange Class 600 designed for high-pressure applications.

- Class 300: Flanges suitable for moderate-pressure applications.

SS 304 Flange 2500, 2500# SS 304 Flanges, Stainless Steel 304 2500 Class Flanges Specifications

| Specification Of : |

Weld Neck Stainless Steel Flanges |

| JIS Standards |

5K, 10K, 40K, 16K 20K 30K, 63K |

| Size Of Bore Diameter Flange |

NPS ≤ 10 |

| Manufacturer Of Standard Dimensions |

EN-1092 Flange, ASME B16.48 Flange, API605 Flange, BS4504 Flange, EN1092 Flange, UNI

Flange, ISO Flange, API7S-43 Flange, ANSI/ASME B16.5 Flange, API7S-15 Flange, MSS

S44 Flange, IS 2062 Flange, ASME B16.36 Flange, DIN Flange, AWWA C207 Flange, B16.47

Series A & B Flange, BS1560-3.1 Flange, ISO70051 Flange, API Flange, ASME Code for

12 inches Welding Neck Flanges.

|

| Minimum Pressure |

150# To 2500# |

| Flange Face Type |

Raised Face, Groove And Small Tongue Groove, RTJ, Weld Neck Flanges Flat Face, Large

Tongue & Large

Male-Female And Small Male-Female, Lap-Joint Face. |

| Top Six Type Of Flanges |

Threaded, Lap Joint, Socket-Weld, Blind, Slip-On or Weld Neck Flanges

|

| Standard Materials |

Duplex Steel & Super Duplex Steel, Copper Nickel, Wrought Iron, Inconel, Mild Steel,

Stainless Steel, Hastelloy, Cast Iron, Alloy Steel, Carbon Steel.

|

| Thickness Length |

NPS ≤ 18

|

| Welding neck flanges size |

(1/2") To (48")

|

| Manufacturing Process |

Forged/ Machined/ Heat Treated

|

| Other Type Of Flange |

Forged/ Plate/ Threaded

|

| Application |

Oil And Gas Industry

Power Plants Industry

Food Processing And Manufacturing

Waterworks Systems

Fossil Fuel Power Plants

Nuclear Power Application

Municipal Pipe Systems

|

Please find below our other manufacturing and Sales network in India : (Contact us

for detailed information for your nearest branches)

- Stainless Steel 304 2500 Class flanges manufacturer and Manufacturer in Mumbai, India.

- Stainless Steel 304 2500 Class flanges manufacturer and supplier in Nagpur, India.

- Stainless Steel 304 2500 Class flanges manufacturer and stockists in Pune, India.

- Stainless Steel 304 2500 Class flanges manufacturer and Exporter in Thane, India.

- Stainless Steel 304 2500 Class flanges manufacturer and wholesalor in Nashik, India.

Frequently Asked Questions

What is a stainless steel weldneck flange?

A stainless steel weldneck flange is a type of pipe flange designed to be welded onto the

neck of a pipe. It provides a smooth, high-strength connection for joining pipes,

valves, and other equipment. All the standard Flange dimensional sizes are

Readily available at any Naysha Steel branch in India.

What types of stainless steel material grades are used for weldneck flanges?

Common stainless steel materials include 304, 316, and 321, among others. The choice of

stainless steel grade depends on the specific application and the required corrosion

resistance.

What sizes are available for stainless steel weldneck flanges?

Stainless steel weldneck flanges are available in a wide range of sizes, typically

ranging from 1/2 inch to several feet in diameter. The size you need depends on your

specific piping system requirements. All the standard Flange dimensional sizes are

Readily available at any Naysha Steel branch in India.

Can stainless steel weldneck flanges be used with other pipes?

Yes, stainless steel weldneck flanges can be used with pipes made of other materials,

provided the flange material is compatible with the pipe material, and the connection is

properly sealed.

Industries served by Stainless Steel SS 304 2500 Class Flanges In Mumbai, India

In the oil and gas industry, blind Alloy Steel flanges are used in pipelines, storage tanks, and offshore platforms. They are employed for closing off openings during maintenance, repair, or when a branch connection is not required. Petrochemical plants utilize blind Alloy Steel flanges in equipment such as reactors, distillation columns, and storage vessels. These flanges provide a secure and leak-proof seal when closing off unused openings or isolating sections of the process.

Oil and Gas Industries

The oil and gas industry includes a wide range of from drilling and

production to refining and marketing. Some of the major players in this

include oil and gas companies, service providers, equipment.

Petroleum Industries

In the drilling process, stainless steel is used to make drill bits, pipes, and other

equipment that must withstand high pressures and temperatures. Stainless steel is

also used to make pumps, valves, and fittings for the transportation.

Shipbuilding in India

In storage applications, stainless steel is used to make tanks and containers that

can safely store corrosive and hazardous chemicals. It is also used in piping

systems for chemical transfer and distribution chemical industry.

Marking & Pricing

Products are packaged to ensure that there is no damage during of goods transport. In case of exports, standard export packaging is done with utmost care in wooden covering or boxing. All products are marked with Grade, Lot No, Size, Degree and our trade mark. On special requests we can also, make

customized marking on our products.

Quality Assurance

At Naysha Steel, all fittings and flanges are subject to strict inspection at each and every stage of the production process, from starting material

purchasing to product dispatch. They are visually examined for compliance to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards.

Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality compliance

of products.

Test Certificates: Manufacturer Test Certificate as per EN 10204 / 3.1B Raw Materials Certificate, 100% Radiography Test Report, Third

Party Inspection Report