Stainless Steel Flanges Manufacturer and Supplier In Mumbai, India

Stainless steel flanges are ring-shaped fittings with a raised face that are used to connect two pipes, valves, or other piping components together. They are commonly made from austenitic stainless steel grades such as 304 and 316, which are known for their excellent corrosion resistance. Stainless steel flanges are available in a variety of types and sizes, and can be connected to pipes using various methods, including welding, threading, and bolting. Stainless steel flanges offer numerous advantages over other types of flanges, including excellent corrosion resistance, high strength and durability, ability to handle high pressures and temperatures, easy to clean and maintain and long service life. Some of the most common types of stainless steel flanges include weld neck flanges, slip-on flanges, blind flanges, lap joint flanges, threaded flanges and socket weld flanges. Stainless steel flanges are used in a broad range of industrial and commercial projects, including chemical processing, food and beverage processing, pharmaceutical manufacturing, power generation, oil and gas production, water and wastewater treatment, marine and offshore applications, aerospace and defense.

Naysha Steel manufactures and supplies Stainless Steel Flanges of various shapes and sizes with unique specifications and clients’ requirements. Naysha Steel stainless steel 304h flanges are reputed and well known for their reliability and quality. Stainless Steel 304 flanges of Naysha Steel are designed and developed in accordance with international and national quality standards. Naysha Steel is offering market-leading prices on SS Flanges to all our customers, with a stock of standard, sizes, and types available for immediate delivery. We manufacture stainless steel square flange with sizes ranging from 1/2" (15 NB) to 48" (1200NB). Naysha Steel has an established and strict quality system with more than 100 approvals and certifications following various industry standards, dimensions and grades like ANSI/ASME B16.5, ANSI/ASME B 16.47 Series A & B, ASTMA TP321, etc. These approvals and certifications help us supply Naysha Steel Flanges to major end-users across a diverse list of suppliers industries. Also, the stainless steel flange price supplied by us is quite reasonable and can easily fit at your budget in manufacturers Mumbai, India.

Types of Stainless Steel Flanges

Naysha Steel, a leading manufacturer and supplier of ibr stainless steel flanges in Mumbai, offers a extensive range of flange types to cater to assorted industrial requirements. First, there are stainless steel 310 slip on plate flanges which are ideal for low-pressure applications and also to provide strength and prevent leakage. Secondly, the stainless steel weld neck flange are suitable for high-pressure and high-temperature environments because of their excellent structural strength. For the benefit of the pipe flanges that can be attached without welding, the threaded flanges are an optimal choice. 316 stainless steel blind flanges, on the other hand, permits easy access to vessels or piping systems for inspection purposes. Socket Weld flanges can be used in high pressure systems. Lastly, orifice flanges are used to measure flow of commodity. Naysha Steel ensures ace quality and authencity across all their stainless steel flange offerings, guaranteeing client satisfaction. Along with these we also specifically manufacture and supply flanges like 2 inch stainless steel flange, 6 stainless steel flange, 3 inch stainless steel exhaust flange, blank flange dn 40 cf stainless steel 304l and various other stainless steel flanges. These come in various classes like 150#, 300# and 600#.

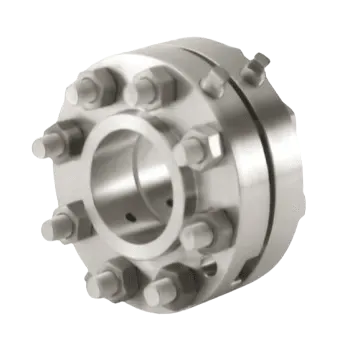

ANSI 16.5 Weld neck flange have a long tapered hub and are often used for high-pressure applications. These flanges are designed in such a way that it is joined by bun welding to piping system. The neck or hub transfers stresses to the pipe, reducing stress concentrations at the flange base. The steady thickness changes from the hub base to the wall thickness at the bun weld provides critical flange reinforcement. The turbulence and erosion is reduced because the bore of the flange matches the bore of the pipe.

These are fitted and welded easily into various pipes. A ASTMA TP304 slip-on pipe flange is strong and leakage-proof because it is slipped over the pipe and then welded both inside and outside. These flanges are excellent for lower pressure applications. A slip-on flange is a type of pipe fitting with an internal shoulder or groove that fits over the end of a pipe. The flange has internal shoulder or grooves with opening in circular shape. The collar slips over the outside diameter of the pipe and is held together by welding or bolting.

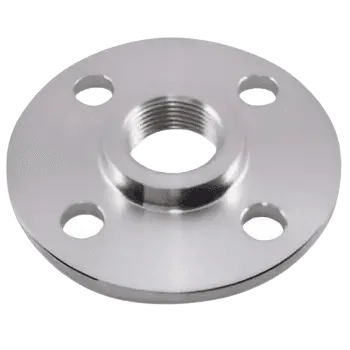

This is same to a certain extent to a slip-on flange in layout, but the bore is threaded, thus enabling assembly without welding. ASTMA TP304L Threaded flanges are used with pipes having external threads. The welding of flange around the joint after the assembly is generally not needed.

ASTMA TP316 Stainless steel 321 blind flanges is a boreless flange that is used to shut off a piping system or vessel opening. Manufacturers can sell blind flanges with or without hubs. Blind flanges is used for inspection purposes because it allows easy access to the inside of the vessel or piping system.

This is similar to a slip-on flange in framework with the only difference being that the bore is counter-bored to accept pipe. The diameter of the remaining bore and inside diameter of the pipe are equal. The ASTMA TP316L Socket Weld Flange is connected to the pipe by a fillet welded around the metal flange hub. It allows for a smooth bore which enables a better flow of the fluid or gas inside. Socket-weld pipe flanges are mainly used for high-pressure pipes that are smaller in size.

A raised face slip on flanges is a slip on pipe flanges that is flat-faced or has a raised face. In BS 10 SORF flanges, a ring groove has been assembled into it. It is known as ‘raised face’ as the gasket surfaces are raised above the bolting circle face. In processing plants applications, slip on flanges with raised faces are the most frequently used.

The function of an orifice flange is to provide connection to a line for measuring of gases or liquids. BS EN-1092 Orifice Flanges are used in place of standard pipe flanges when installation of orifice plate or flow nozzle in necessary. Combination of pressure tappings are assembled into the orifice flange, making separate orifice carriers or tappings in the pipe wall necessary. An orifice plate is locked between a couple of flanges when installed in a line and the whole body is referred to as an orifice flange union.

Get an estimate within 10 minutes!

Features of Stainless Steels Flanges

One of the key features of stainless steel 321 pipe flanges is their ability to

withstand high temperatures and pressures. They are commonly used in industries such as oil and

gas, chemical processing, and food and beverage processing. 304 stainless steel flanges are also

highly resistant to oxidation, making them suitable for use in environments with high humidityffffff

and moisture levels. Duplex stainless steel flanges are available in different shapes, sizes,

and configurations, making them adaptable to a range of applications in market of metal india. They can be welded or

bolted onto pipes and are compatible with different materials, including carbon steel, copper,

and PVC. The significant feature of en 1092-1 flanges and a240 flat flange stainless steel is their excellent

corrosion resistance properties. Features of these flanges vary according to different specifications like DIN, ANSI/ASME B16.48, BS 4504, etc.

Size of

Stainless Steel Flanges

| Nominal Size |

Outside Diameter

(OD) |

Min. Thickness

(T) |

RF Dia.

(R) |

No. of Bolt Holes |

Diameter of Holes |

Bolt Circle

(BC) |

SO Bore ID

(SB) |

WN Bore ID

(WB) |

Dia. Hub Base

(HB) |

Dia. of Hub Top

(HT) |

SO LTH

(SL) |

WN LTH

(WL) |

| 1⁄2 |

3.50 |

0.38 |

1.38 |

4 |

0.62 |

2.38 |

0.88 |

0.62 |

1.19 |

0.84 |

0.56 |

1.81 |

| 3⁄4 |

3.88 |

0.44 |

1.69 |

4 |

0.62 |

2.75 |

1.09 |

0.82 |

1.50 |

1.05 |

0.56 |

2.00 |

| 1 |

4.25 |

0.50 |

2.00 |

4 |

0.62 |

3.12 |

1.36 |

1.05 |

1.94 |

1.32 |

0.62 |

2.12 |

| 11⁄4 |

4.62 |

0.56 |

2.50 |

4 |

0.62 |

3.50 |

1.70 |

1.38 |

2.31 |

1.66 |

0.75 |

2.19 |

| 11⁄2 |

5.00 |

0.62 |

2.88 |

4 |

0.62 |

3.88 |

1.95 |

1.61 |

2.56 |

1.90 |

0.81 |

2.38 |

| 2 |

6.00 |

0.69 |

3.62 |

4 |

0.75 |

4.75 |

2.44 |

2.07 |

3.06 |

2.38 |

0.94 |

2.44 |

| 21⁄2 |

7.00 |

0.81 |

4.12 |

4 |

0.75 |

5.50 |

2.94 |

2.47 |

3.56 |

2.88 |

1.06 |

2.69 |

| 3 |

7.50 |

0.88 |

5.00 |

4 |

0.75 |

6.00 |

3.57 |

3.07 |

4.25 |

3.50 |

1.12 |

2.69 |

| 31⁄2 |

8.50 |

0.88 |

5.50 |

8 |

0.75 |

7.00 |

4.07 |

3.55 |

4.81 |

4.00 |

1.19 |

2.75 |

| 4 |

9.00 |

0.88 |

6.19 |

8 |

0.75 |

7.50 |

4.57 |

4.03 |

5.31 |

4.50 |

1.25 |

2.94 |

| 5 |

10.00 |

0.88 |

7.31 |

8 |

0.88 |

8.50 |

5.66 |

5.05 |

6.44 |

5.56 |

1.38 |

3.44 |

| 6 |

11.00 |

0.94 |

8.50 |

8 |

0.88 |

9.50 |

6.72 |

6.07 |

7.56 |

6.63 |

1.50 |

3.44 |

| 8 |

13.50 |

1.06 |

10.62 |

8 |

0.88 |

11.75 |

8.72 |

7.98 |

9.69 |

8.63 |

1.69 |

3.94 |

| 10 |

16.00 |

1.12 |

12.75 |

12 |

1.00 |

14.25 |

10.88 |

10.02 |

12.00 |

10.75 |

1.88 |

3.94 |

| 12 |

19.00 |

1.19 |

15.00 |

12 |

1.00 |

17.00 |

12.88 |

12.00 |

14.38 |

12.75 |

2.12 |

4.44 |

| 14 |

21.00 |

1.31 |

16.25 |

12 |

1.12 |

18.75 |

14.14 |

13.25 |

15.75 |

14.00 |

2.19 |

4.94 |

| 16 |

23.50 |

1.38 |

18.50 |

16 |

1.12 |

21.25 |

16.16 |

15.25 |

18.00 |

16.00 |

2.44 |

4.94 |

| 18 |

25.00 |

1.50 |

21.00 |

16 |

1.25 |

22.75 |

18.18 |

17.25 |

19.88 |

18.00 |

2.62 |

5.44 |

| 20 |

27.50 |

1.62 |

23.00 |

20 |

1.25 |

25.00 |

20.20 |

19.25 |

22.00 |

20.00 |

2.81 |

5.62 |

| 22 |

29.50 |

1.75 |

25.25 |

20 |

1.38 |

27.25 |

22.22 |

21.25 |

24.25 |

22.00 |

3.07 |

5.82 |

| 24 |

32.00 |

1.81 |

27.25 |

20 |

1.38 |

29.50 |

24.25 |

23.25 |

26.12 |

24.00 |

3.19 |

5.94 |

Uses of Stainless Steel Flanges

- Stainless steel 317 flanges or 317l stainless steel flanges are often used in construction for structural applications such as roofing,

bridges, and building facades. It is also used in the manufacturing of stainless steel

reinforcement bars for concrete structures.

- 347 stainless steel flanges or 347h stainless steel flanges is a popular material for cookware, cutlery, and other kitchen appliances

due to its non-reactive properties and resistance to staining and corrosion.

- Our stainless steel 310 flanges are widely used in the medical industry for surgical instruments, implants,

and medical devices due to its biocompatibility and ease of sterilization.

- Stainless steel flanges supplied by us is used in the manufacturing of various automotive components such as

exhaust systems, trim, and grilles due to its resistance to corrosion and durability.

- 316 stainless steel flanges are used extensively in the oil and gas industry for pipes, valves, and other

equipment due to its resistance to corrosion in harsh environments.

Stainless Steel Flanges Chemical Composition

| Grade |

Chemical Composition(%) |

| Carbon |

Manganese |

Phosphorus |

Sulfur |

Silicon |

Nickel |

Chromium |

Molybdenum |

Titanium |

Other |

| F304 |

0.080 |

2.00 |

0.045 |

0.030 |

1.00 |

8.0-11.0 |

18.0-20.0 |

--- |

--- |

N0.10 |

| F304L |

0.030 |

2.00 |

0.045 |

0.030 |

1.00 |

8.0-13.0 |

18.0-20.0 |

--- |

--- |

N0.10 |

| F316 |

0.080 |

2.00 |

0.045 |

0.030 |

1.00 |

10.0-14.0 |

16.0-18.0 |

2.00-3.00 |

--- |

N0.10 |

| F316L |

0.030 |

2.00 |

0.045 |

0.030 |

1.00 |

10.0-15.0 |

16.0-18.0 |

2.00-3.00 |

--- |

N0.10 |

| F321 |

0.080 |

2.00 |

0.045 |

0.030 |

1.00 |

9.0-12.0 |

17.0-19.0 |

--- |

I |

N0.10 |

Quality of Stainless Steel Flanges manufacturing in Mumbai, India

The grade of stainless steel used to manufacture the flange plays a significant role

in determining its quality. Different grades of stainless steel have different chemical

compositions, which affects their resistance to corrosion and other environmental factors. For

example, austenitic stainless steel grades such as 304 stainless steel flanges and 316ti stainless steel flanges are commonly used in flanges installed by our clients all over United Arab Emirates, manufacturing due to their excellent corrosion resistance and high strength. The manufacturing

process used to produce the flange also affects its quality. These metric stainless steel flanges can be produced using

different methods, including forging, casting, and machining. Each method has its advantages and

disadvantages in terms of cost, lead time, and quality. For example, forged flanges are

generally considered to be of higher quality than cast flanges due to the superior strength and

durability of the forged product. Finally, we manufacture and supply high-quality stainless steel flanges which come in use across various domains and industries.

Get an estimate within 10 minutes!

Stainless Steel Flanges Manufacturer Mumbai, India : Grades & Classes

- Grade stainless steel 304l flanges/stainless steel 304 flanges: This is the most common stainless steel grade, offering good corrosion resistance and excellent weldability.

- Grades 310 stainless steel flange: Known for its excellent performance

- Grade stainless steel 316l flanges/stainless steel 316 flanges: Known for its superior corrosion resistance, especially in environments with chlorides or acids.

- Grades 321 stainless steel flange/321h stainless steel flanges: Contains titanium, offering high temperature resistance and excellent weldability.

- Grade 347: Contains niobium, providing improved high-temperature strength and resistance to intergranular corrosion.

- Grade stainless steel 904l flanges: Offers excellent resistance to chloride-induced stress corrosion cracking.

- Class 150: Designed for low-pressure applications.

- Class 300: Suitable for moderate-pressure applications.

- Class 600: Intended for high-pressure and high-temperature applications.

- Class 900: Used in severe high-pressure and high-temperature environments.

Stainless Steel Flanges Manufacturer and Supplier in Mumbai, India:- Specifications:

| Specification Of : |

Stainless Steel Flanges |

| JIS Standards |

5K, 10K, 40K, 16K 20K 30K, 63K |

| Size Of Bore Diameter Flange |

NPS ≤ 10 |

| Manufacturer supplier Of Standard Dimensions |

EN-1092, ASME B16.48, API605, BS4504, EN1092, UNI, ISO, API7S-43, ANSI/ASME B16.5, API7S-15, MSS S44, IS 2062, ASME B16.36, DIN, AWWA C207, B16.47 Series A & B, BS1560-3.1, ISO70051, API.

|

| Minimum Pressure |

150# To 2500# |

| Flange Face Type |

Raised Face, Groove And Small Tongue Groove, RTJ, Flat Face, Large Tongue & Large Male-Female And Small Male-Female, Lap-Joint Face. |

| Type Of Flanges Manufacturer supplier india |

Threaded, Lap Joint, Socket-Weld, Blind, Slip-On, Weld Neck |

| Standard Materials |

Duplex Steel & Super Duplex Steel, Copper Nickel, Wrought Iron, Inconel, Mild Steel, Stainless Steel, Hastelloy, Cast Iron, Alloy Steel, Carbon Steel.

|

| Thickness Length |

NPS ≤ 18

|

| Size |

(1/2") To (48")

|

| Manufacturing Process |

Forged/ Machined/ Heat Treated

|

| Other Type Of Flange |

Forged/ Plate/ Threaded

|

| Application |

Food Processing And Manufacturing

Waterworks Systems

Oil And Gas Industry

Power Plants Industry

Municipal Pipe Systems

Fossil Fuel Power Plants

Nuclear Power Application

|

Please find below our manufacturing and Sales network below: (Contact us for detailed information for your nearest branches)

- Stainless Steel Flanges manufacturer and contractor in Hyderabad

- Stainless Steel Flanges manufacturer and supplier in Chennai

- Stainless Steel Flanges manufacturer and stockists in Pune

- Stainless Steel Flanges manufacturer and dealer in Faridabad

- Stainless Steel Flanges manufacturer and warehousing in Chandigarh

- Stainless Steel Flanges manufacturer and wholesalor in Delhi

- Stainless Steel Flanges manufacturer and trader in Coimbatore

- Stainless Steel Flanges manufacturer and stockholder in Bangalore

Frequently Asked Questions

What is a stainless steel flange and how to buy one in Mumbai or a metro city like Mumbai in India?

A stainless steel flange is a circular component used to connect pipes, valves, pumps, and other equipment in a piping system. It provides a means for easy assembly and disassembly of these components. Naysha Steel offers stainless steel flanges at the shortest lead time, as we are a major stockholder of SS Flanges in Mumbai, India. We have the capacity to fulfil huge quantities of orders in a day in metro cities like Mumbai in India and not more than 2-3 days in any part of India

How do I choose the right size and class of stainless steel flanges for my application?

The size and class of a stainless steel flange depend on factors such as pipe size, pressure rating, temperature, and application requirements. Consult us, at Naysha Steel is recommended for proper selection.

Are there any special considerations when working with stainless steel flanges in Mumbai, India?

Yes, stainless steel flanges require proper handling to avoid contamination and damage specially for a city like Mumbai as there is alot of construction and machinery work undertaken at a very fast pace. Welding should be done using appropriate techniques for stainless steel to maintain corrosion resistance. This also applies to other locations where the application is crucial

Industries served by Stainless Steel Flanges

In the oil and gas industry, blind Alloy Steel flanges are used in pipelines, storage tanks, and offshore platforms. They are employed for closing off openings during maintenance, repair, or when a branch connection is not required. Petrochemical plants utilize blind Alloy Steel flanges in equipment such as reactors, distillation columns, and storage vessels. These flanges provide a secure and leak-proof seal when closing off unused openings or isolating sections of the process.

Oil and Gas Industries

The oil and gas industry includes a wide range of from drilling and

production to refining and marketing. Some of the major players in this

include oil and gas companies, service providers, equipment.

Petroleum Industries

In the drilling process, stainless steel is used to make drill bits, pipes, and other

equipment that must withstand high pressures and temperatures. Stainless steel is

also used to make pumps, valves, and fittings for the transportation.

Shipbuilding in India

In storage applications, stainless steel is used to make tanks and containers that

can safely store corrosive and hazardous chemicals. It is also used in piping

systems for chemical transfer and distribution chemical industry.

Marking & Pricing

Products are packaged to ensure that there is no damage during of goods transport. In case of exports, standard export packaging is done with utmost care in wooden covering or boxing. All products are marked with Grade, Lot No, Size, Degree and our trade mark. On special requests we can also, make

customized marking on our products.

Quality Assurance

At Naysha Steel, all fittings and flanges are subject to strict inspection at each and every stage of the production process, from starting material

purchasing to product dispatch. They are visually examined for compliance to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards.

Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality compliance

of products.

Test Certificates: Manufacturer Test Certificate as per EN 10204 / 3.1B Raw Materials Certificate, 100% Radiography Test Report, Third

Party Inspection Report